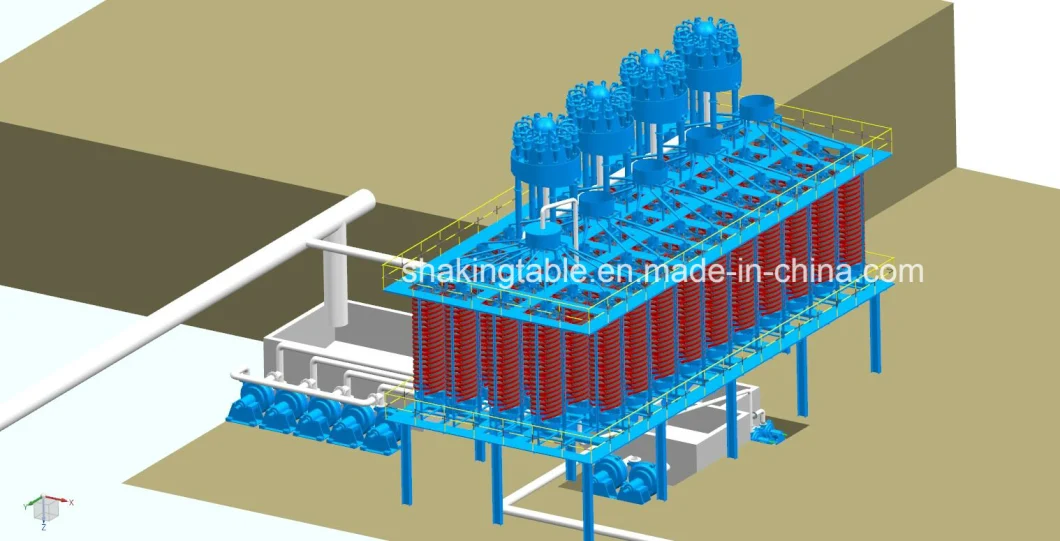

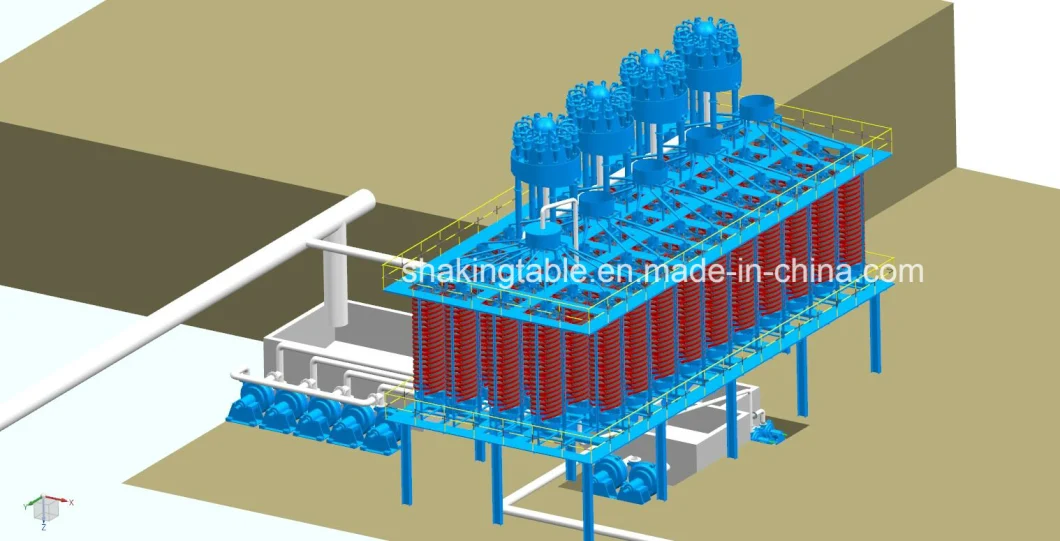

High quality zircon ore spiral chute for zircon mining process

How is works: Ore pulps are uniformly fed into machine and form different layers as they pass across chute. Heavy minerals precipitate to bottom and are moved toward inner edge by the comprehensive action of various forces; light minerals are moved toward outer inner due to the speedy rotation. As a result, mineral particles with different density are divided into three zones---concentrate, middling and tailing.

How is works: Ore pulps are uniformly fed into machine and form different layers as they pass across chute. Heavy minerals precipitate to bottom and are moved toward inner edge by the comprehensive action of various forces; light minerals are moved toward outer inner due to the speedy rotation. As a result, mineral particles with different density are divided into three zones---concentrate, middling and tailing.

Spiral concentrator (spiral chute) is a gravity separation equipment of separation different weight mineral by inertial centrifugal force pulp produced in helix turning motion, it widely used in enrichment of particle size 0.3-0.02mm fine minerals like iron, tin, chromite, ilmenite, tungsten, zinc, tantalum-niobium, gold, coal , monazite, rutile, zircon and other low-grade ores, and non-metallic minerals which have a big enough specific gravity difference.

Our spiral concentrator (spiral chute) is made of the fiberglass lined with wear-resistant resin and emery cover; the advantages are light, moisture proof, anti-rust, wear proof, anti corrosion, no noise and non power required.

Our spiral concentrator (spiral chute) is made of the fiberglass lined with wear-resistant resin and emery cover; the advantages are light, moisture proof, anti-rust, wear proof, anti corrosion, no noise and non power required.

Main technical parameters of spiral concentrator (spiral chute)

Main technical parameters of spiral concentrator (spiral chute)

FAQ:

Q:You are factory or trade company?

A:We are the biggest gravity separator machine manufacturer in China.we have 7 modem

workshops, one sample test workshop and one office building.

Q:If your company can provide whole line machine?

A:Yes, From washing to get final gold bar.

Q:What's capacity you can provide?

A:All machine can customization,we can provide from 20t/h-300t/h.

Q:If can arrange engineer come to worksite for installation?

A:Yes.

If you have mining plant such as Tin,Tantalum-Niobium,Chrome,Monazite,copper,manganese,zinc ore

in Africa or Southeast Asia or central South America,

but haven't money,we can introduce investor to you.

or if you have ore, but have't found buyer,

we can introduce buyers to you.

For more details, please don't hesitate to Contact us, you can send us inquiry as below, we will reply you within 24hours.

How is works: Ore pulps are uniformly fed into machine and form different layers as they pass across chute. Heavy minerals precipitate to bottom and are moved toward inner edge by the comprehensive action of various forces; light minerals are moved toward outer inner due to the speedy rotation. As a result, mineral particles with different density are divided into three zones---concentrate, middling and tailing.

How is works: Ore pulps are uniformly fed into machine and form different layers as they pass across chute. Heavy minerals precipitate to bottom and are moved toward inner edge by the comprehensive action of various forces; light minerals are moved toward outer inner due to the speedy rotation. As a result, mineral particles with different density are divided into three zones---concentrate, middling and tailing.Spiral concentrator (spiral chute) is a gravity separation equipment of separation different weight mineral by inertial centrifugal force pulp produced in helix turning motion, it widely used in enrichment of particle size 0.3-0.02mm fine minerals like iron, tin, chromite, ilmenite, tungsten, zinc, tantalum-niobium, gold, coal , monazite, rutile, zircon and other low-grade ores, and non-metallic minerals which have a big enough specific gravity difference.

Our spiral concentrator (spiral chute) is made of the fiberglass lined with wear-resistant resin and emery cover; the advantages are light, moisture proof, anti-rust, wear proof, anti corrosion, no noise and non power required.

Our spiral concentrator (spiral chute) is made of the fiberglass lined with wear-resistant resin and emery cover; the advantages are light, moisture proof, anti-rust, wear proof, anti corrosion, no noise and non power required.

Main technical parameters of spiral concentrator (spiral chute)

Main technical parameters of spiral concentrator (spiral chute)| Model | 5LL-2000 | 5LL-1500 | 5LL-1200 | 5LL-900 | 5LL-600 | 5LL-400 |

| Diameter (mm) | 2000 | 1500 | 1200 | 900 | 600 | 400 |

| Spiral Pitch (mm) | 1200 | 720/540 | 720/540 | 540/405 | 450/360 | 240/180 |

| Starts | 3 | 4 | 4 | 4 | 2 | 2 |

| Feeding size (mm) | 4-0.04 | 0.8-0.037 | 0.3-0.03 | 0.3-0.03 | 0.2-0.02 | 0.2-0.02 |

| Feeding density (%) | 20-45 | 30-60 | 25-35 | 25-55 | 25-55 | 25-55 |

| Capacity (t/h) | 15-40 | 6-8 | 4-6 | 2-3 | 0.4-0.8 | 0.15-0.2 |

| Length (mm) | 2300 | 1560 | 1360 | 1060 | 700 | 460 |

| Width (mm) | 2300 | 1560 | 1360 | 1060 | 700 | 460 |

| Height (mm) | 6500 | 5230 | 5230 | 4000 | 2600 | 1500 |

| Weight (Kg) | 1100 | 800 | 600 | 400 | 150 | 50 |

Q:You are factory or trade company?

A:We are the biggest gravity separator machine manufacturer in China.we have 7 modem

workshops, one sample test workshop and one office building.

Q:If your company can provide whole line machine?

A:Yes, From washing to get final gold bar.

Q:What's capacity you can provide?

A:All machine can customization,we can provide from 20t/h-300t/h.

Q:If can arrange engineer come to worksite for installation?

A:Yes.

If you have mining plant such as Tin,Tantalum-Niobium,Chrome,Monazite,copper,manganese,zinc ore

in Africa or Southeast Asia or central South America,

but haven't money,we can introduce investor to you.

or if you have ore, but have't found buyer,

we can introduce buyers to you.

For more details, please don't hesitate to Contact us, you can send us inquiry as below, we will reply you within 24hours.