Naipu® factory of slurry pump , gravel sand pump , dredging pump and spare parts.

The Pumps are widely used in in metallurgy, mining, Nonmetallic Mining, Coal, Energy

resources, Sand mining, Dredging, Environmental protection, Petrochemical engineering, Flue gas desulfurization and other industrial departments.

Field Applications:

Heavy Mining | Mineral Processing | Coal Prep | Cyclone Feeds | Aggregate Processing | Fine Primary Mill Grinding | Chemical Slurry Service | Tailings | Secondary Grinding | Industrial Processing | Pulp And Paper | Food Processing | Cracking Operations | Ash Handling | Pipeline Transport | High Velocity Hydraulic Transport |Food Processing | Explosive Sludge In Metal Smelting | River And Pond Dredging | Heavy Refuse Removal | Larger Particle Or Low NPSHA Applications | Continuous (Snore) Sump Pump Operation | Abrasive Slurries | High Density Slurries || Large Particle Slurries | Sump Drainage | Washdown | Floor Drainage | Mixing

Gravel Sand Slurry Pump

TYPE NOTATION

14X12G-NP-G

14 ---- Suction Size : 14 inch

12------Discharge Size: 12 inch

G---- Base type

NP-- Shijiazhuang NaiPu Pump Co.,Ltd

G--- Gravel Sand dredge Pump

NP-G GRAVEL SAND PUMP PERFORMANCE PARAMETERS

Model | Flow(m3/h) | Head(m) | Speed(r/min) | Efficiency(%) | NPSHr/m | Max permissible particle size/mm |

6X4D-NP-G | 187-36 | 7-51 | 1400-600 | 30-58 | 1.5-3.7 | 82 |

8X6E-NP-G | 576-133 | 10-48 | 1400-800 | 60-54 | 1.2-4.2 | 127 |

10X8F-NP-G | 930-216 | 11-44 | 940-500 | 65-34 | 3-7 | 178 |

12X10G-NP-G | 1512-360 | 11-58 | 850-400 | 70-50 | 1.5-6 | 220 |

14X12G-NP-G | 3168-522 | 9.5-66 | 700-300 | 68-60 | 2-8.5 | 241 |

16X14TU-NP-G | 3024-900 | 14-45 | 500-300 | 70-50 | 3.5-6.5 | 254 |

10X8F-NP-GH | 1091-324 | 19.2-56.5 | 800-500 | 72-60 | 1.5-5 | 180 |

12X10G-NP-GH | 2232-612 | 28-77 | 700-450 | 73-60 | 1.5-8 | 210 |

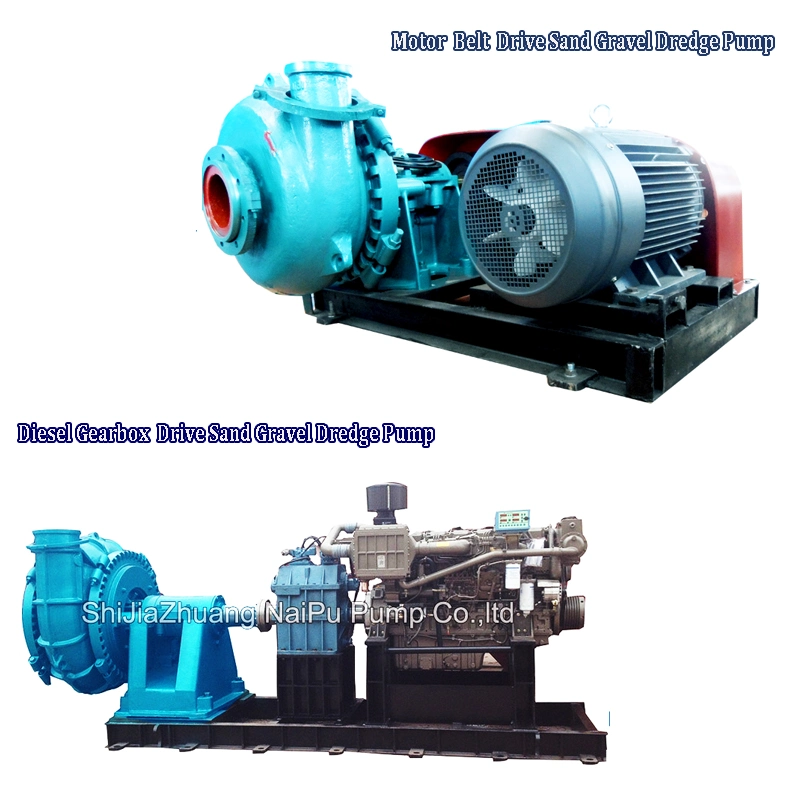

The Gravel Sand Pump can be drived by Motor or Diesel

Basic Description:

Naipu dredge and gravel slurry pumps are designed for the continuous

handling of the most difficult higher abrasive slurries, containing solids

too large to be pumped by a standard slurypump.

They are suitable for delivering slurries in Mining, explosive sludge in

metal melting, dredging in Dredger and course of rivers and other fields.

Feature

--Made with high chromium abrasion resistance alloy

-- Wide wet passage

--Discharge direction of pump can be oriented in any direction of 360.

--Easy installation and operation

--Good Performance of NPSH

--Abrasion-resistance

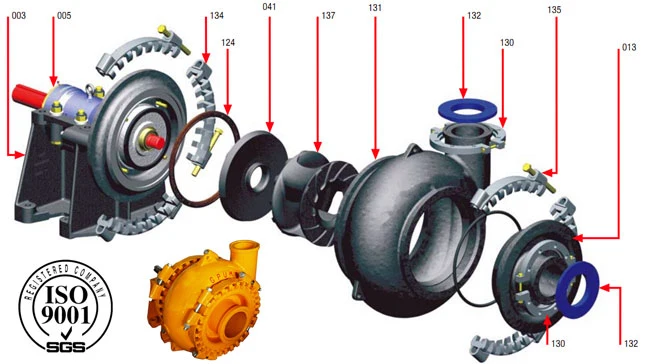

Construction for gravel sand pump

| 003:Base 005:Bearing Assembly 132:Intake Joint Discharge Joint 130:Discharge Flange Intake Flange 013:Cover Plate | 131:Bowl 137:Impeller 041:Back Liner 135:Door Clamp Ring 134: Adapter Plate Clamp Ring 124:Volute Cover Seal |

Materials of Construction

| VOLUTE | IMPELLERS | BASE | EXPELLER | EXPELLER RING | SHAFT SLEEVE | SEALS | |

| Standard | High Chrome Alloy | High Chrome Alloy | Cast Iron | Chrome Alloy or SG Iron | Chrome Alloy or SG Iron | SG Iron | Natural Rubber |

| Options | SG Iron | SG Iron | Mild Steel Fabricated | SG Iron | SG Iron | EN56C Ferralium Hasteloy C Ceramic Stellite Chrome Oxide | Nordel Neoprene Viton Butyl EPDM |

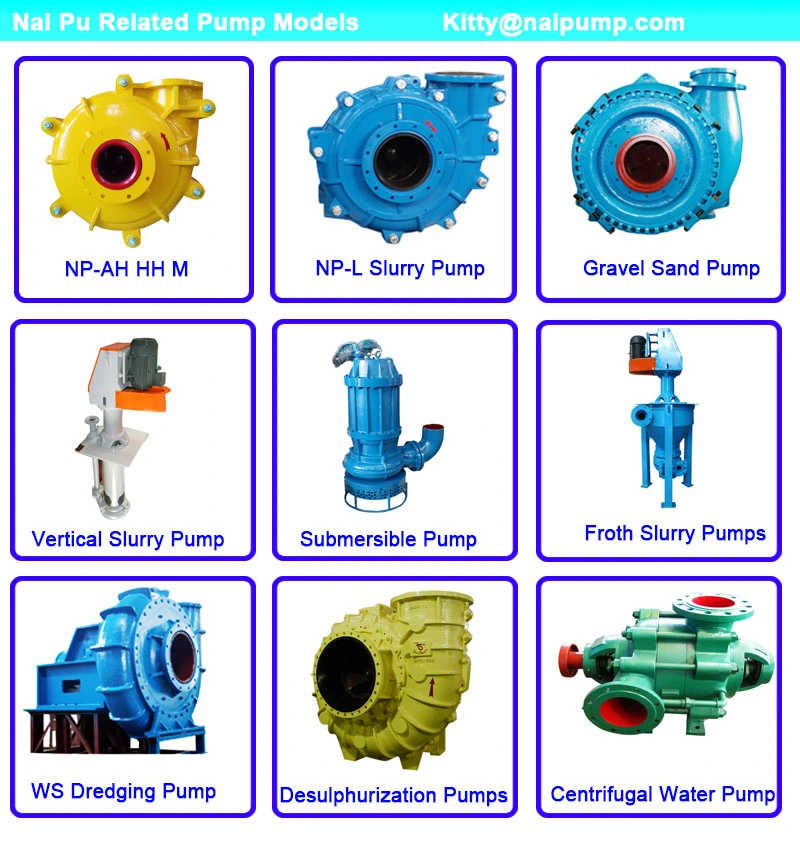

Related Naipu Pumps

Metal Liner (Rubber Liner ) Heavy Duty Slurry Pump AH TYPE

1.5/1B-AH 2/1.5B-AH 3/2C-AH 3/2CC-AH 4/3C-AH 4/3CC-AH 4/3D-AH 4/3DD-AH 6/4D-AH 6/4DD-AH 6/4E-AH 6/4EE-AH 8/6E-AH 8/6EE-AH 8/6F-AH 8/6FF-AH 8/6R-AH 10/8ST-AH 10/8F-AH 10/8FF-AH 12/10ST-AH 12/10G-AH 12/10F-AH 12/10FF-AH 14/12ST-AH 14/12G-AH 14/12FF-AH 14/12F-AH 16/14TU-AH 20/18TV-AH

Metal Liner (Rubber Liner )Vertical Slurry Pump SP TYPE

40PV-SP 65QV-SP 100RV-SP 150SV-SP 200SV-SP 250SV-SP

Metal Liner High Head slurry pump HH TYPE

1.5/1C-HH 3/2D-HH 3/2DD-HH 4/3E-HH 4/3EE-HH 6/4F-HH 6/4FF-HH 6/4x- HH 6S-H 8/6S-H 8/6X-H 6S-HP 8/6S-HP 8/6X-HP

Metal Liner (Rubber Liner)Slurry Pump M TYPE

10/8E-M(R) 10/8R-M(R)

Metal Liner (Rubber Liner)Frothy Slurry Pump AF TYPE

2QV-AF(R) 3QV-AF(R) 6SV-AF(R) 8SV-AF(R)

Metal Liner Gravel Pump G TYPE

6/4D-G 6/4DD-G 6/4E-G 8/6E-G 8/6EE-G 10/8F-G 10/8FF-G 10/8S-G 12/10F-G 12/10FF-G 12/10G-G 14/12F-G 14/12FF-G 14/12G-G 10/8S-GH 10/8F-GH 10/8FF-GH 12/10G-GH 12/10F-GH 12/10FF-GH 14/12G-G 14/12T-G 18/16 T-G

Metal Liner (Rubber Liner ) Slurry Pump L TYPE

20A-L 50B-L 50B-LR 75C-L 100D-L 150E-L 300S-L

Main Slurry Pump Parts : Impeller , Volute Liner , Casing , ThroatBush, Frame Plate Liner Insert , Cover Plate , Frame Plate, Pump Liner Expeller , Expeller Ring ,Stuffing Box , Expeller , Pump Shaft , shaft sleeve, Shaft Spacer, Bearing Assembly , Base, Stuffing Box, Gland Assembly, Bearing Housing , Lantern Ring , pump discharge pipe , flange , and so on.

Model Workshop --casting Work Shop-- Machining workshop--assembly workshop--stockage

The slurry pump are widely used in mining, power , metallurgy , coal, dredging, building material and other industrial lines to pump concentrate , tailings, sludge and other abrasive , high density slurries.

1.Quick Reply.All Message or email will get reply within 8 hours

2.We can help to select the suitablepump if you can not sure which model pump suitable for you

3.We have a group of high quality technicians with rich experience who can solve everything during the whole process.

4.Perfect after -sales .We will be responsible for the whole life period

5.OEM order.Many material are available ,like High chrome, rubber , stainless steel and etc.,

ShiJiaZhuang NaiPu Pump Co.,Ltd

Contact person :Kitty Liu

Mobile :+86-13032609126

Shijiazhuang, Headquarters

Add.:No.368, Xinshi North Road, Shijiazhuang, Hebei Province, China

If you are intrested in sand suction pump, please do not hesitate to contact us!