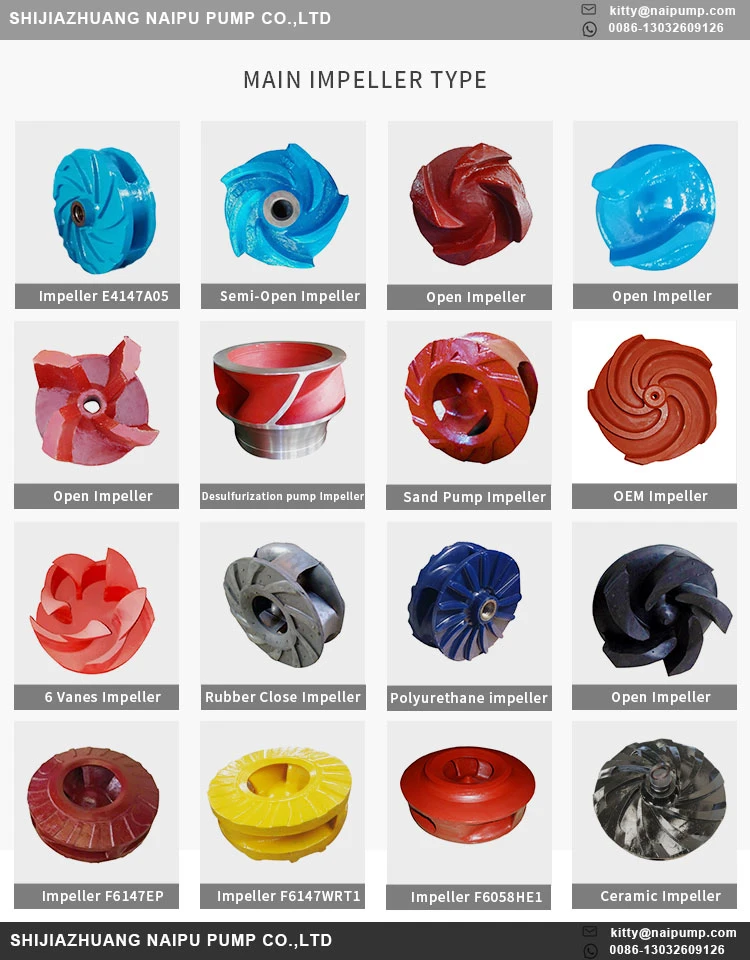

Impeller of Anti-Wear High Performance High Chrome Casting

Shijiazhuang NaiPu Pump Co.,ltd --- Direct Factory of Slurry Pump , Sand Gravel Pump , Dredging Pump and Wear parts.

The pump and pump parts can totally interchange with AH HH M L SP AF G Series.

Welcome to visit our factory.

Looking for distributor and agent all the world.

Wear Resistant Slurry Pump Parts Material : High Chrome alloy or Nature Rubber

Frame Plate Liner Insert- Slurry Pump Part

High Chrome Mud Slurry Pump Part Impeller

Main Slurry Pump Parts

Main pump parts :Cover plate , Frame Plate, Impeller, Pump Liner , Volute Liner , Throat Bush, Frame plate Liner Insert, Back Liner , Expeller, shaft , shaft sleeve, stuffing box,base, Bearing Assembly, Shaft Spacer, base,gland assembly, lantern restrictor and so on.

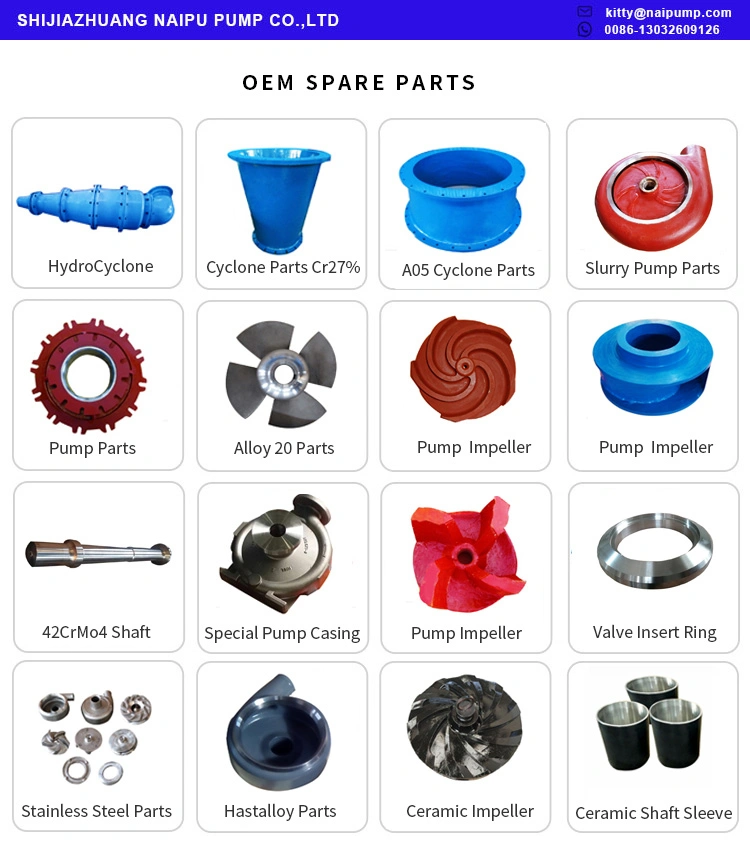

OEM Service

Based on many years of rich experience in slurry pump manufacturing and design, NAIPU can undertake OEM customization for the whole set of pump and various spare parts. The slurry pump spare parts can be made of various material according to customer's requirement, Such as : Alloy 20, Hastelloy Alloy , A 61 and so on.

Metal Material

| Code | Material # | Hardness HRC | Performance | Application |

| A05 | KmTBCr26 | ≥56 | Ranks second only to A07 in abrasion-resistant performance; fair corrosion-resistant performance. | High impact load abrasion condition; PH rate ranging from 5 to 12 |

| A07 | KmTBCr15Mo3 | ≥59 | Best abrasion-resistant performance; corrosion-resistant performance is inferior to A05 | High impact load abrasion condition |

| A33 | ≥35 | Abrasion-resistant performance is close to A03; fair corrosion-resistant performance | Oxide slurry with PH rate no less than 1, like phosphor-gypsum in phosphate fertilizer plant, nitric acid, sulph-oacid and phosphoric acid, etc. | |

| A49 | ≥43 | Fair abrasion-resistant performance, close to A03; fair corrosion-resistant performance in media with lower PH rate. | Corrosion conditions with low PH rate, especially for flue gas and FGD devices for media of PH≥4; general suitable for lower acid condition. | |

| A12 | ≥62 | Higher abrasion-resistant performance than A05; fair corrosion-resistant performance; suitable for media with PH rate is 6-16, where A05 is not suitable. | High abrasive slurry with fine particles. | |

| A61 | 63-68 | Optimized abrasion-resistant performance than A12 | High abrasive slurry with fine particles. |

Rubber Material

| Material | Material # | Applications |

| Natural Rubber | R08 | R08 is low to medium hardness rubber used for impellers where slurry contains fine particles and erosive. |

| Natural Rubber(soft) | R26 | R26 is soft natural rubber used for liners where slurry contains fine particle and more erosive. |

| Natural Rubber(soft) | R33 | R33 is widely used for frame plate liners, cover plate liners and impellers. Maximal particle diameter is 10mm; impeller peripheral speed should be less than 25m/s; suitable for temperature not exceeding 75ºC. |

| Natural Rubber | R55 | R55 is widely used for impellers, frame plate liners, cover plate liners and throat bushes. Maximal particle diameter can be 20mm, impeller peripheral speed should be less than 27.5m/s; suitable for temperature not exceeding 75ºC. |

| EPDM Rubber | S01 | S01 is widely used for impellers, frame plate liners, cover plate liners and throat bushes. Maximal particle diameter can be 8mm; impeller peripheral speed should be less than 25m/s; suitable for temperature not exceeding 120ºC(continuous duty) or 140ºC(discontinuous duty). |

| Nitrile Rubber(NBR) | S12 | S12 is widely used for frame plate liners, cover plate liners, throat bushes, lip seals, impellers and expellers. Maximal particle diameter is 7mm; impeller peripheral speed should be less than 27m/s; suitable for temperature not exceeding 95ºC. |

| Butyl Rubber | S21 | S21 is widely used for impellers, frame plate liners, cover plate liners, expellers, volute seals and throat bushes,. Maximal particle diameter can be 7mm; impeller peripheral speed should be less than 30m/s; suitable for temperature not exceeding 100ºC. |

| Hypalon | S31 | S31 can be used for impellers, frame plate liners, cover plate liners and throat bushes,. It is recommended to use for strong acid slurry with mild or moderate corrosion. Maximal particle diameter can be 10mm; impeller peripheral speed should be less than 30m/s; suitable for temperature not exceeding 110ºC. |

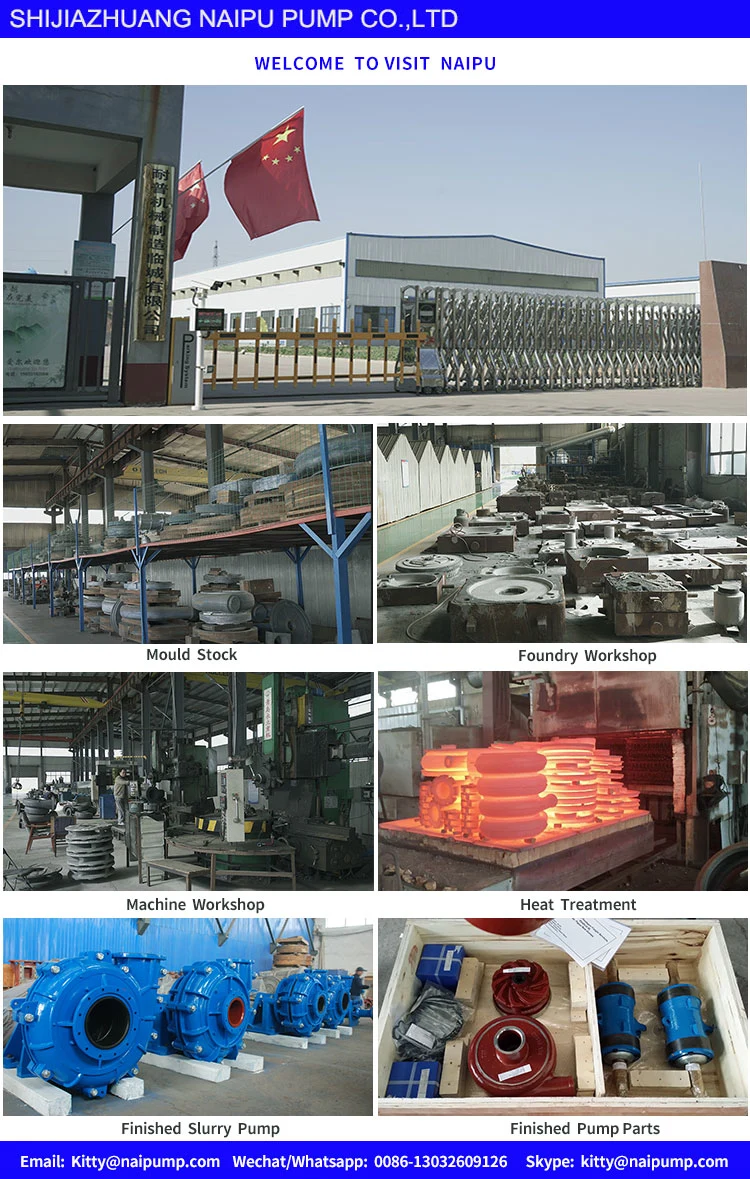

Company Information

Shijiazhuang Naipu Pump Co., Ltd Is a professional Manufacturering Enterprise of slurry pumps and pump parts, for about 30 years.

We have Model workshop, casting workshop, machining workshop, assembly workshop.

We undertake OEM order as customer's drawing

Our products are widely used in mining, metallurgy, coal washing, power plant, sewage water treatment, dredging, chemical and petroleum industries.

The Pumps have been exported to USA, Canada, Germany, Russia , Australia, South Asia, North America, South Africa, and etc , up to more than sixty countries.

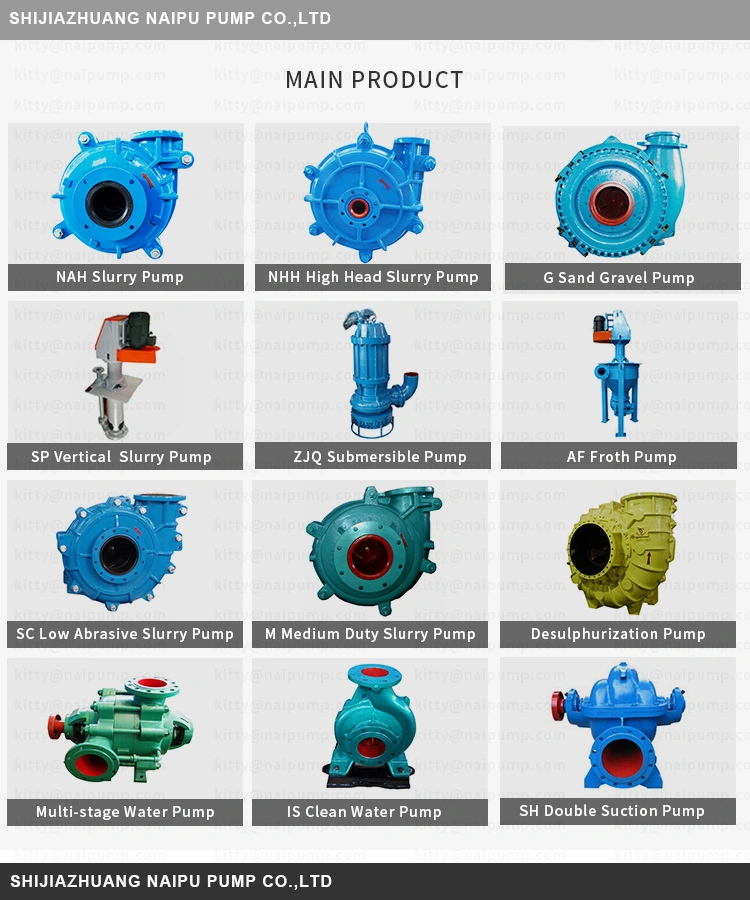

NaiPu Main products

1. AH ,HH,M Horizontal Slurry Pump

2. SP Vertical sump pump

3. ZJQ Submersible slurry pump

4. G Horizontal sand gravel pump

5. ZJQ Submersible sand pump

6. WS Dredging pump

7. AF,AHF, Froth Pump

8. TL(R) Desulphurization Pump

8.Clean Water Pump

9. OEM Casting machinery parts

Main Pump Model

| NAH series | L(R) ,M | HH | SP(R) | G | AF Series |

| 1.5/1B-NAH(R) | 20A-L | 1.5/1 C-HH | 40PV-SP(R) | 6/4D-G | 2QV-AF |

| 2/1.5B-NAH(R) | 50B-L(R) | 3/2D-HH | 65QV-SP(R) | 8/6E-G | 3QV-AF |

| 3/2C-NAH(R) | 75C-L | 4/3E-HH | 100RV-SP(R) | 10/8F-G | 6SV-AF |

| 4/3C-NAH(R) | 100 D-L | 4/3X-HH | 150SV-SP(R) | 10/8S-G | 8SV-AF |

| 6/4D-NAH(R) | 150E-L | 6/4F-HH | 200SV-SP | 12/10G-G | 2AHF |

| 6/4E-NAH(R) | 300S-L | 6/4X-HH | 250TV-SP | 14/12G-G | 3AHF |

| 8/6E-NAH(R) | 10/8 R-M | 6S-H | 14/12T-G | 4AHF | |

| 8/6R-NAH(R) | 10/8 E-M | 8/6S-H | 16/14 G-G | 6AHF | |

| 10/8F-NAH(R) | 12/10F-M | 8/6X-H | 16/14TU-GH | ||

| 10/8X-NAH(R) | 6S-HP | 16/14H-GH | |||

| 12/10ST-NAH(R) | 8/6S-HP | 18/16G-G | |||

| 14/12ST-NAH(R) | 8/6X-HP | 18/16 TU-GH | |||

| 16/14TU-NAH(R) | |||||

| 20/18G(TU)-NAH(R) |

Workshop

| Factory Name | Shijiazhuang NaiPu Pump Co.,Ltd |

| Manufacturer or Trading Company | Manufacturer |

| Workshop | Foundry, Machining, Assembly |

| Year the company was established | 2007.01.10 |

| Number of employees | 162 |

| Designed capacity of factory | 3,000.T Resin Sand 2500T Lost Foam Casting 500T |

| Factory area in m2 | 330,000m2 |

| Does the factory record rejects. If so what is the reported reject rate for past 12 months. | Yes, We record. the reported reject rate for past 12 months =7.6% |

| Quality System Certification | ISO9001-2015, CE, |

| Types of Material the company produces | Ductile Iron Chrome Iron Alloy Steel Rubber |

| Melting Equipment | Induction 2T X 2 |

| Non destructive inspection equipment. | Ultrasonic testing equipment UT Dye penetrant testing PT |

| Typical products the foundry makes | Slurry Pump Wet End Parts Hydrocyclone Parts Wear resistant castings Other Wear Parts |

| Minimum and maximum casting weight for each moulding system | Max. 6.0T , Min. 3Kg |

Our Service

1.Quick Reply

Your inquiry related to our products or prices will be replied within 12 hours.

2.We have a group of high quality technicians with rich experience who can solve everything during the whole process.

3.Guarantee quality, All the products have proved by ISO 9001:2008, CE, SGS.And also will be inspected strictly before delivery.

4.Perfect after -sales .We will be responsible for the whole life period

5.OEM order.Many material are available ,like High chrome, rubber , stainless steel and etc.Steely alloy,

Contact Us

ShiJiaZhuang NaiPu Pump Co.,Ltd

Contact person :Kitty Liu

Shijiazhuang, Headquarters

Add.:No.368, Xinshi North Road, Shijiazhuang, Hebei Province, China