Why choose us?

- Specialized production Manufactory for many kinds of diesel water pumps

- Focus on R&D for improvement

- Experienced in Domestic and oversea market

- Carefully paint or plastic powder coated ensuring good appearance

- Years of International service standards, Engineer one-to-one service

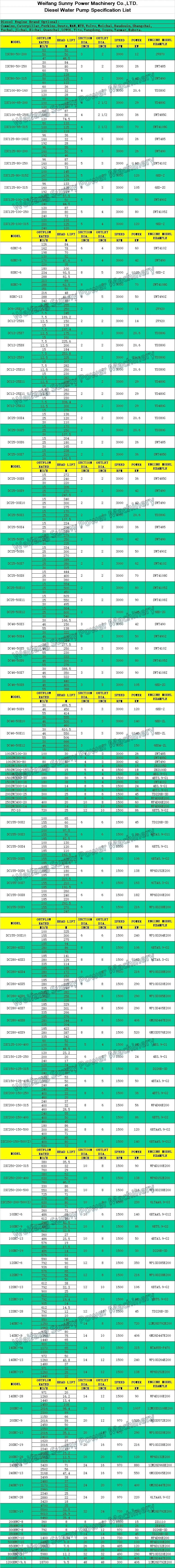

Main Parameters:

| Diameter | 2-48inch(DN50-1200mm) |

| Outflow rate | 6-18700 m3/h |

| Head lift | 5-10000m |

| Liquid Temp. | Max 80 ºC |

Multi-purpose solution:

• Fresh water, river water, rain water

• Slurry & semi solid material

• Well pointing - high vacuum pump capacity

• Fire fighting or building high pressure pump station

• 24 hour reliability

• Designed for high ambient environments

Main applications:

• Building & Construction - well pointing and sump pumping

• Water & Waste - over pumping and systems bypass

• Quarries & Mines - sump pumping

• Emergency Water Control - sump pumping

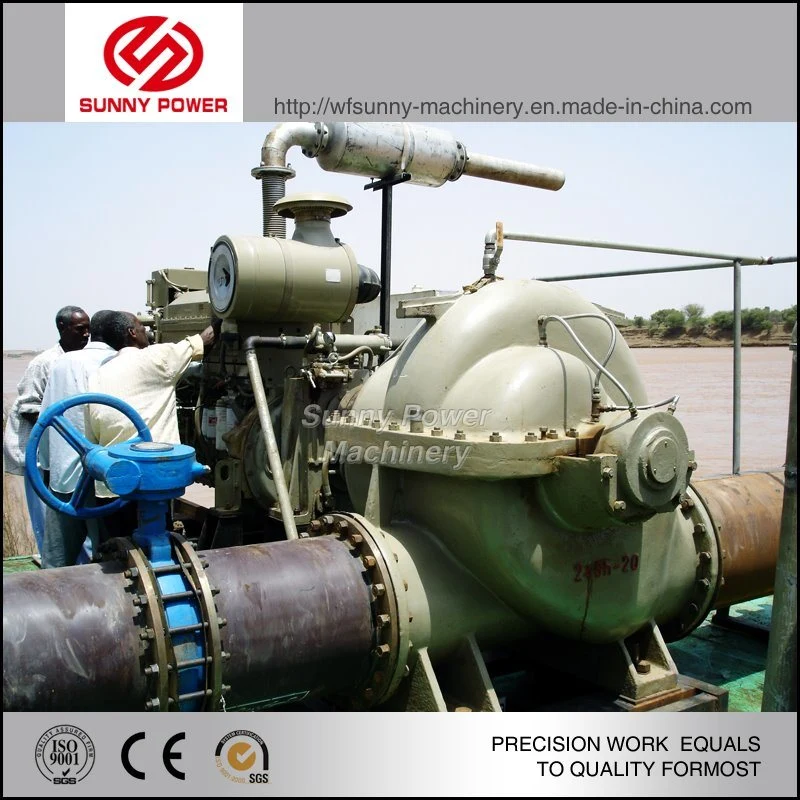

• Docks, Ports & Harbors - sump pumping and stabilization of loads

Standard equipment:

- Diesel engine assembly

- Water pump assembly

- Flexible shaft coupling unit

- Steel mounting skid

- Built-in fuel tank (Additional separate fuel tank is available.)

- Clutch or gearbox

- Battery

- Engine and water pump protection system

- Automatic start and self shut off function(ATS AMF)

- Remote control/off duty control/PC control or mobile phone control

- Trailer and weather canopy

- Suction hose, delivery hose or lay flat hose, PP/PE pipe, wire reinforced PVC or rubber hose.

- Foot valve, gate valve, non-return valve, butter fly valve, pipe fittings and hose clamps

- Engine and water pump additional spare parts relatively.

Packing:

Conventional Packaging suitable for by sea or long distance transportation.

Delivery date:

Regularly, within 3-30 working days after receiving the deposit, special models to be discussed by two parties.

Quality guarantee:

Our company regard quality as our life to achieve the perfect machinery at any time. We are certified by ISO 9001 system and obey the stipulations and management.

Services:

1. One year or 1000 working hours guarantee of whole machine except for wear parts;

2. Technical support by email whole day;

3. Calling service;

4. User's manual available;

5. Installation guide for clients from both China and abroad;

6. Maintance and replacement service;

Contact information:

Frank PAN (General Manager)

Weifang Sunny Power Machinery CO.,LTD.

http://wfsunny-machinery.en.made-in-china.com/

TEL: 0086-536-8366176 FAX: 0086-536-8366176

MOB: 0086-13371069268 / 18663676651