Product description

Ball mill 0.1~100 ton capacity wet & batch type, suitable for glaze and the ceramic raw materials milling. The lining materials can be rubber, stone, medium/high alumina, and the controlling mode can be by normal starter, soft starter and the energy saving controller.

Ball mill 0.1~100 ton capacity wet & batch type, suitable for glaze and the ceramic raw materials milling. The lining materials can be rubber, stone, medium/high alumina, and the controlling mode can be by normal starter, soft starter and the energy saving controller.

| Size | φ2800*3400 | φ3000*5000 | φ3200*5500 | φ3400*6400 | φ3600*7000 | φ3900*8500 | φ4200*10000 |

| Capacity(T) | 10000 | 15000 | 20000 | 30000 | 40000 | 60000 | 100000 |

| Rolling speed(r/min) | 13.8 | 13 | 13 | 13 | 12 | 10.5 | 10 |

| Motor power (KW) | 75 | 90 | 110 | Ishimura-110 CHALCO-132 | Ishimura-132 CHALCO-160 | 250 | 315 |

| Net weight (T) | 18-19 | 20-21 | 21-23 | 24-25 | 28-30 | 41-43 | 58 |

| Dimension (mm) | 5900*5926*3450 | 7650*6848*4260 | 8450*6680*4340 8240*6680*4340 | 9086*7345*4740 | 9800*7090*4850 | 12750*9180*5150 | 15888*9007*5400 |

Product details

Other products

Exhibition

Our Service

Pre-sales

*Help customers to choose product.

*Freely send engineers to the working field to plan the installation site and design the best technical production process.

*Design the special product according to the contract.

After-sales

*Send the engineers to guide the installation.

*Install and adjust the equipment for customers.

*Train the operator for customers.

*We also provide the technical service for our customers after the installation.

Exhibition

Our Service

Pre-sales

*Help customers to choose product.

*Freely send engineers to the working field to plan the installation site and design the best technical production process.

*Design the special product according to the contract.

After-sales

*Send the engineers to guide the installation.

*Install and adjust the equipment for customers.

*Train the operator for customers.

*We also provide the technical service for our customers after the installation.

Certifications

Company information

Company information

Zibo Chaoxin Ceramics Technology Co., Ltd. as a new and hi-tech ceramic manufacturer with excellent abilities of technology research, manufacture and distribution, is located in Zibo National New and High-tech Industrial Development Zone in Shandong Province, China.

We mainly produce various kinds of fine ceramic products, which in material of zirconium oxide (ZrO2), alumina (Al2O3), zirconium silicate (ZrSiO4), mullite (A3S2) and composite oxide ceramics. Products include ceramic grinding ball(diameter 0.3mm~30mm), Ceramic Liner(mud pump spare part), Ceramic Plunger(oil pump spare part), Alumina Lining Bricks(ceramic ball mill machine), Wear-Resistant Sleeves, Wear-Resistant Lining Tiles/Mat, ball mill machine, Cyclone, and chemical ball, etc.

Structural ceramic products are with excellent performances, such as wearing-resistance, erosion-resistance, high-temperature-resistance, high-strength, high-hardness in the working conditions in which metal or polymer ones cannot do. With functions of the most advanced manufacturing equipment in ceramic field, our structural ceramic products such as ceramic liner and ceramic plunger are with better performances(improved by 5 to 10 times), have been used widely in many oilfields and petrochemical enterprises in the chemical industry.

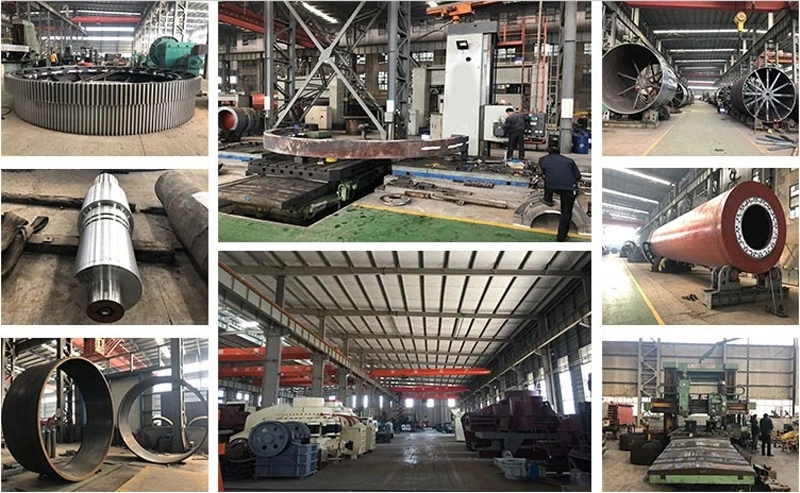

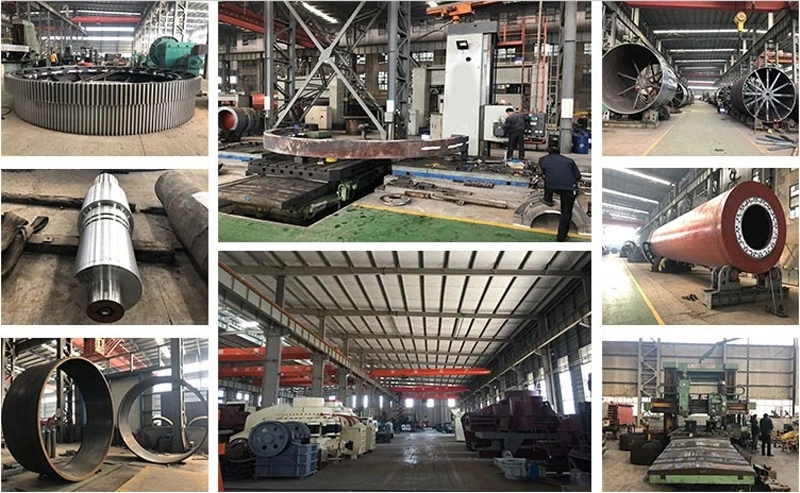

Factory workshop

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. or it is 15-25 work days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: T/T,Alibaba Trade Assurance or L/C

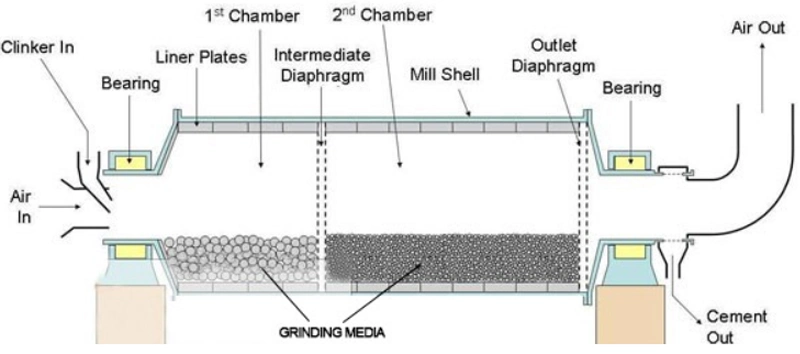

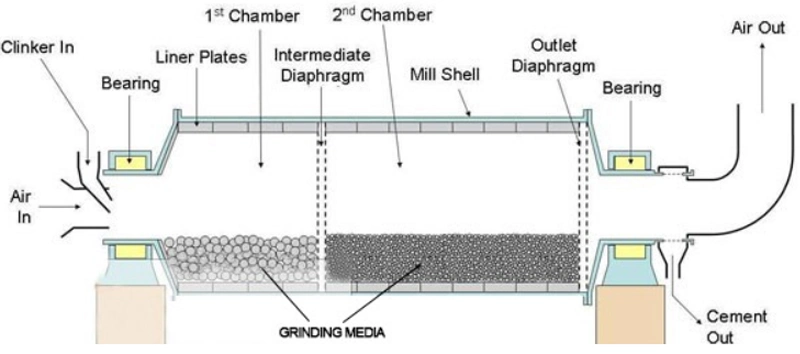

Q: "What's the technique structure of ball mill machine?

A: Cast steel hollow shaft, lined with removable, rotary gear hobbing by casting process, the body inlaid cylinder liner wear, has good wear resistance. Smooth mill operation of the machine, reliable.

Q: "Can introduce the details of several issues when used ball mill to grind rocks?"

A: 1. Additional ball mill should be regularly in order to maintain the best ball mill loading.

2. Running regularly on the recirculation pump, piping and recycling containers to wash, cyclone should also be regularly switch, flush to prevent clogging.

3.Ball mill output should be in the best run, should not easily change the output.

We mainly produce various kinds of fine ceramic products, which in material of zirconium oxide (ZrO2), alumina (Al2O3), zirconium silicate (ZrSiO4), mullite (A3S2) and composite oxide ceramics. Products include ceramic grinding ball(diameter 0.3mm~30mm), Ceramic Liner(mud pump spare part), Ceramic Plunger(oil pump spare part), Alumina Lining Bricks(ceramic ball mill machine), Wear-Resistant Sleeves, Wear-Resistant Lining Tiles/Mat, ball mill machine, Cyclone, and chemical ball, etc.

Structural ceramic products are with excellent performances, such as wearing-resistance, erosion-resistance, high-temperature-resistance, high-strength, high-hardness in the working conditions in which metal or polymer ones cannot do. With functions of the most advanced manufacturing equipment in ceramic field, our structural ceramic products such as ceramic liner and ceramic plunger are with better performances(improved by 5 to 10 times), have been used widely in many oilfields and petrochemical enterprises in the chemical industry.

Factory workshop

Packaging & Shipping

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. or it is 15-25 work days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: T/T,Alibaba Trade Assurance or L/C

Q: "What's the technique structure of ball mill machine?

A: Cast steel hollow shaft, lined with removable, rotary gear hobbing by casting process, the body inlaid cylinder liner wear, has good wear resistance. Smooth mill operation of the machine, reliable.

Q: "Can introduce the details of several issues when used ball mill to grind rocks?"

A: 1. Additional ball mill should be regularly in order to maintain the best ball mill loading.

2. Running regularly on the recirculation pump, piping and recycling containers to wash, cyclone should also be regularly switch, flush to prevent clogging.

3.Ball mill output should be in the best run, should not easily change the output.