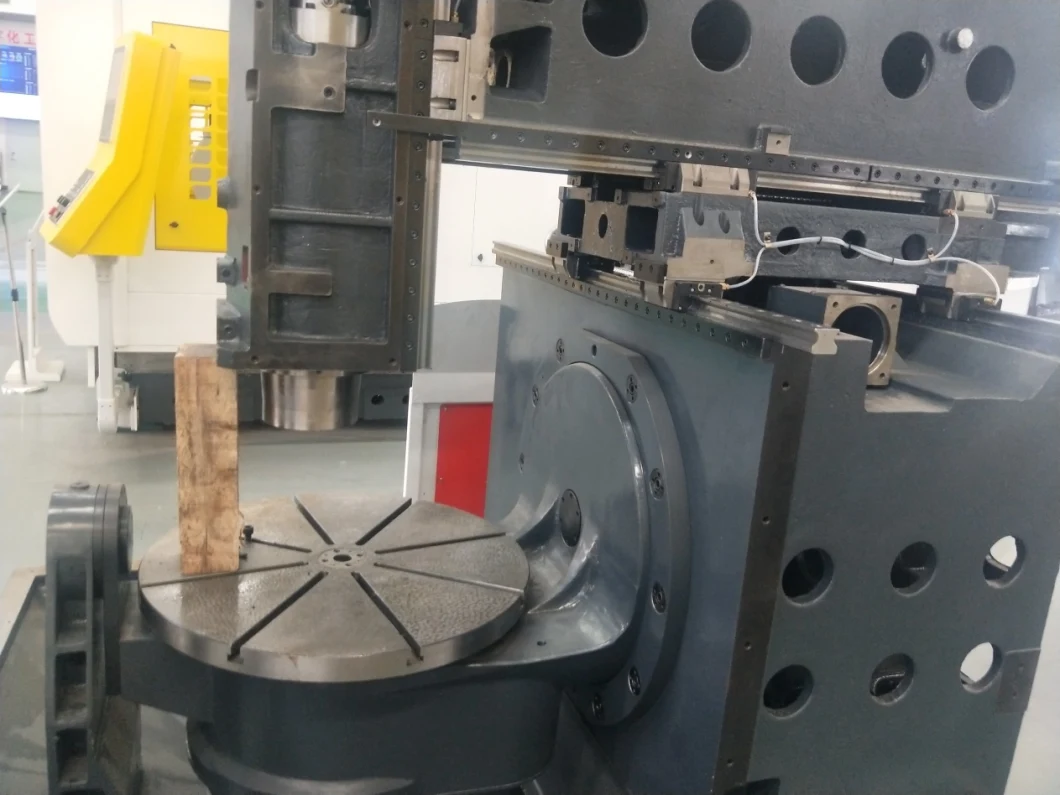

vmc 1075

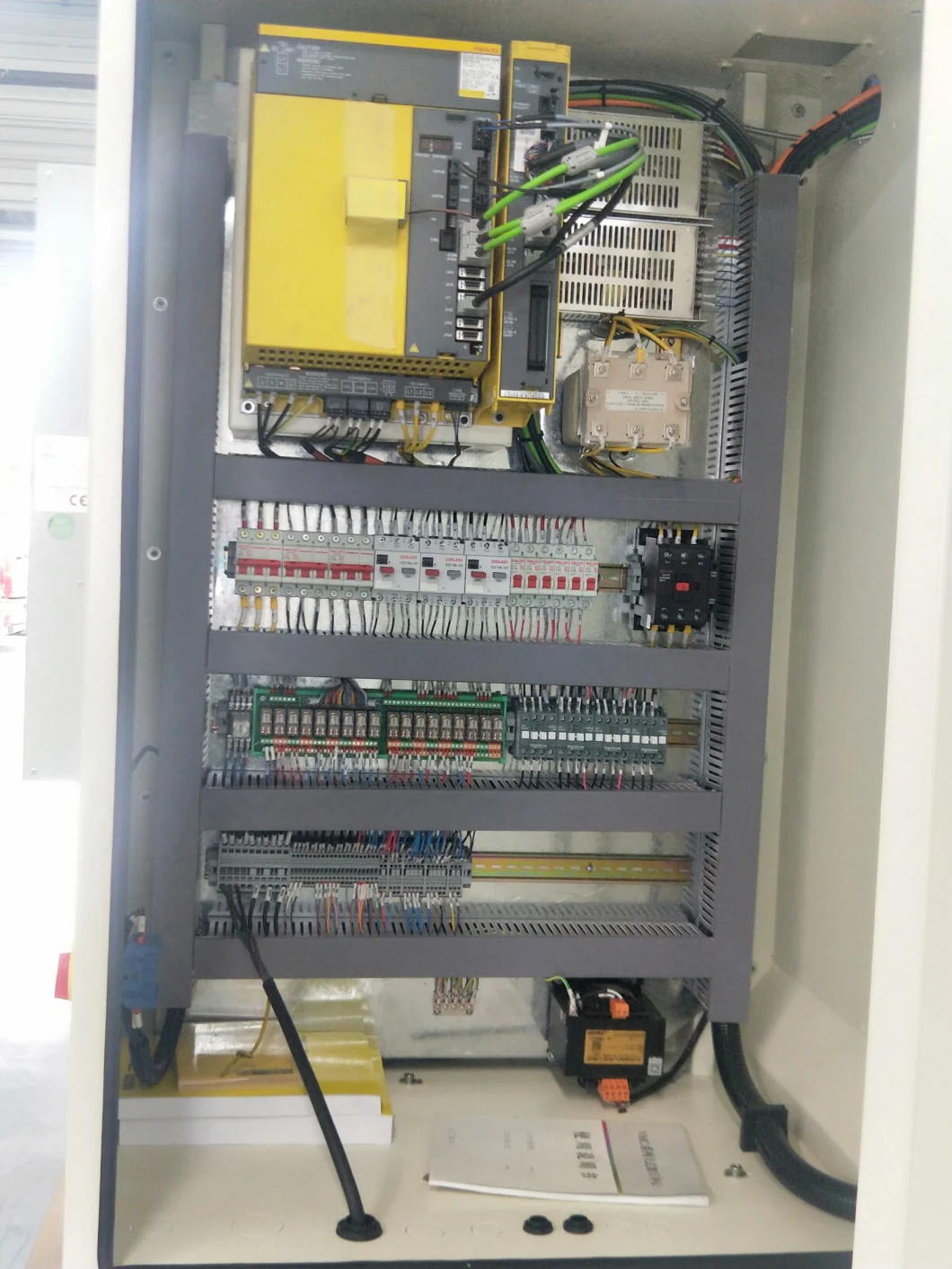

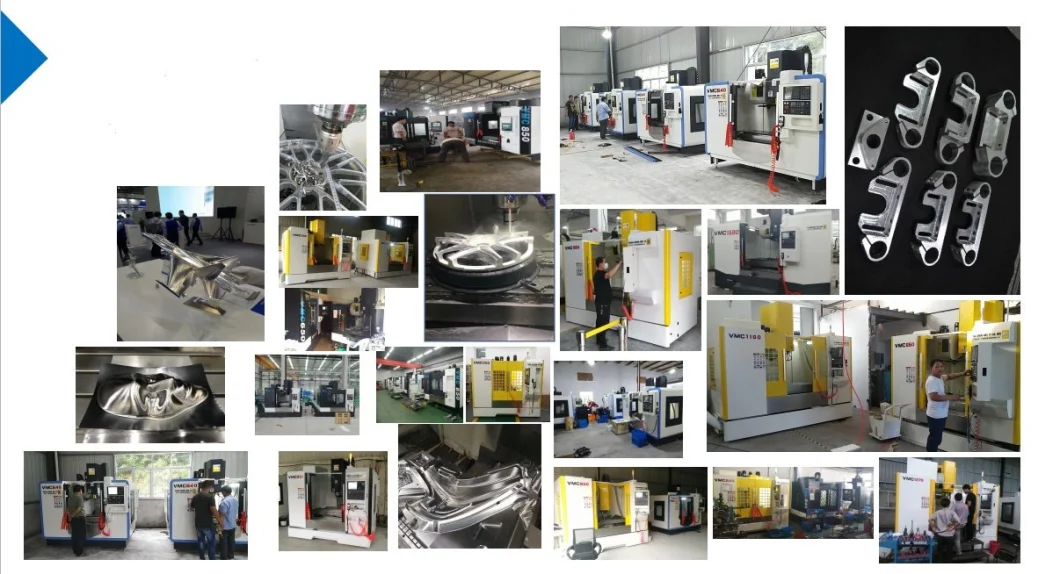

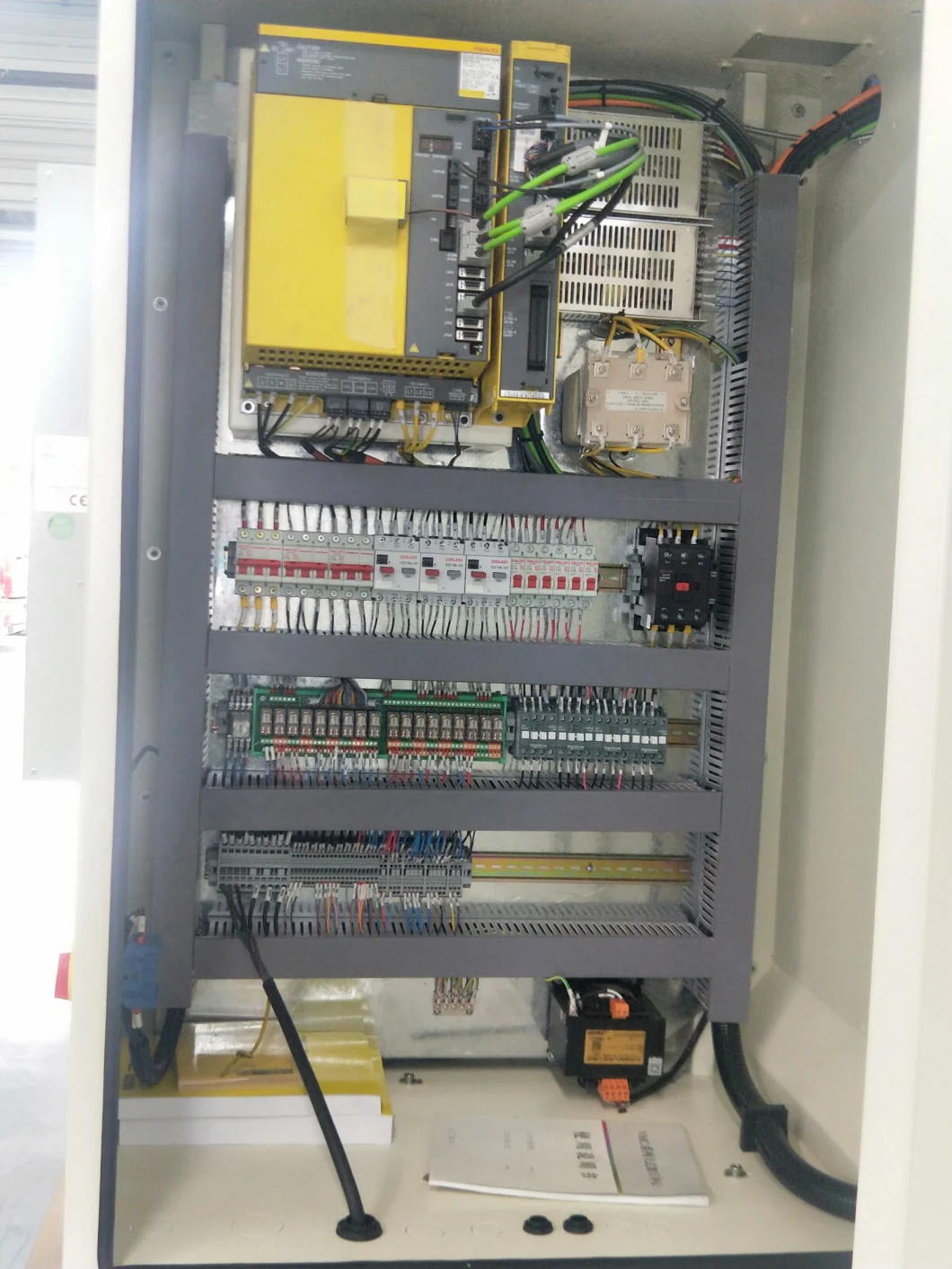

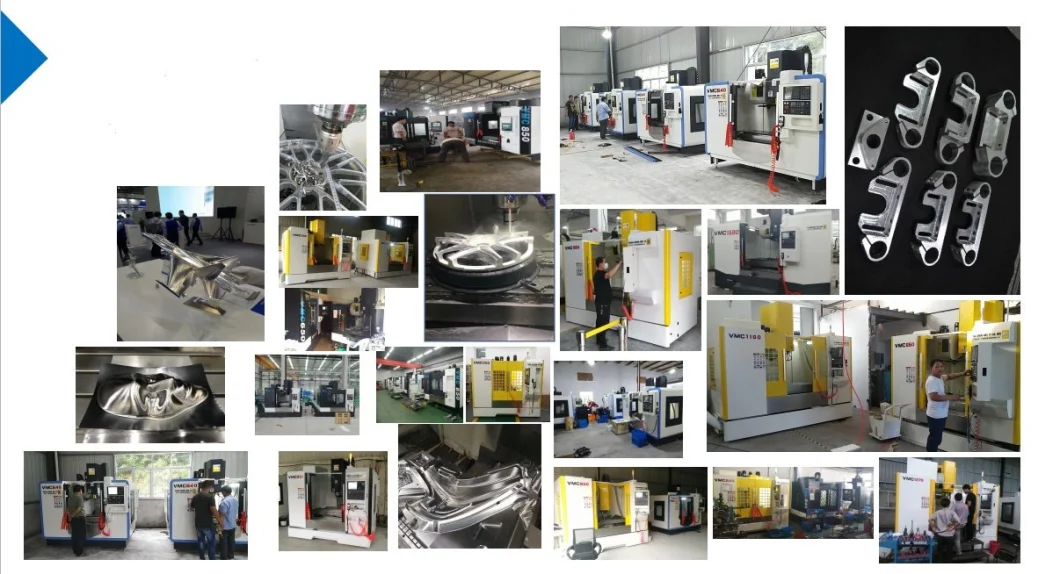

This machine is applied to automobile, engine, aviation, spaceflight, instruments, light industry, light textile, electric devices and mechanical manufacture, etc. For machining parts such as medium or small boxes, covers, plates, shell, disk, etc. --Equipped with CNC system of MITSUBISH E60M or FUNAC Oi Mate Model B.

Features: With auto tool changer; Strong cooling equipment; Apping with rigidity and reliability; High accuracy, high speed, high efficiency, continuous machining, easy operated and security; Full-enclosed guard, Beautiful appearance.

Product Overview

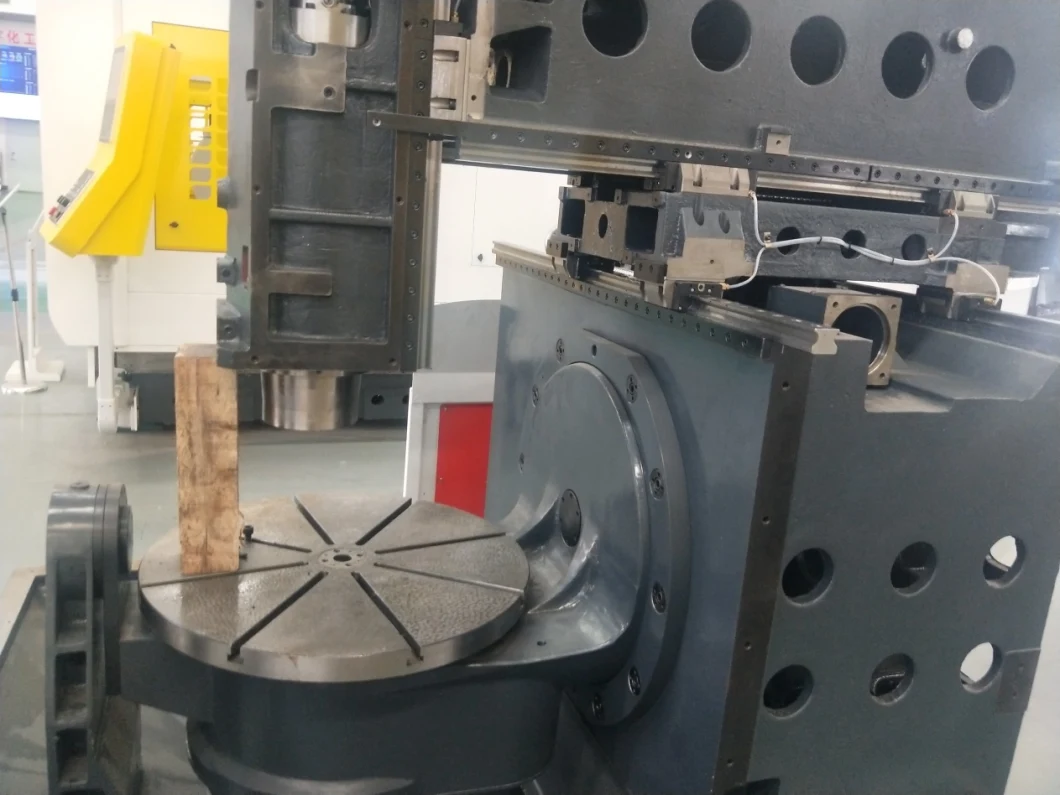

This series vertical machining center adopts the moving structure of cross sliding table and sliding

guide,which is mainly applied in processing of middle and smallscale complicated parts.Apply the

computeraided engineering(CAE)system to finish the optimized structure design and enhance the

reliability of machine tool,and the finite element method(FEM)to take the scientific analysis and

optimization of design structure,which can guarantee the rigidity and stability of the whole machine

structure.It can finish all kinds of processing,such as milling,drilling,expanding,boring,tapping and

profile milling at one time of clamping.It is suitable for the parts processing with high precision,

multipe procedure and complicated shape.It is the key facility in industries of general machinery,

mold,aviation,energy and traffic.

Machine Characteristics

1.The major machine components apply finest gray cast iron which are of good shock resistance.

All the casts have been done with aging treatment twice, in order to eliminate the internal residual

stresses. So that, our machine can work with high rigidity and good shock resistance for heavy cutting and intermittent cutting.

2.Key components are designed with CAD software, in this way, the optimal structure can be

analyzed out by computer, which ensure the good intensity,rigidity and thermal stability.

3.The joint face of components are manually polished well, which guarantees the effective contacting area.

This machine is applied to automobile, engine, aviation, spaceflight, instruments, light industry, light textile, electric devices and mechanical manufacture, etc. For machining parts such as medium or small boxes, covers, plates, shell, disk, etc. --Equipped with CNC system of MITSUBISH E60M or FUNAC Oi Mate Model B.

Features: With auto tool changer; Strong cooling equipment; Apping with rigidity and reliability; High accuracy, high speed, high efficiency, continuous machining, easy operated and security; Full-enclosed guard, Beautiful appearance.

Product Overview

This series vertical machining center adopts the moving structure of cross sliding table and sliding

guide,which is mainly applied in processing of middle and smallscale complicated parts.Apply the

computeraided engineering(CAE)system to finish the optimized structure design and enhance the

reliability of machine tool,and the finite element method(FEM)to take the scientific analysis and

optimization of design structure,which can guarantee the rigidity and stability of the whole machine

structure.It can finish all kinds of processing,such as milling,drilling,expanding,boring,tapping and

profile milling at one time of clamping.It is suitable for the parts processing with high precision,

multipe procedure and complicated shape.It is the key facility in industries of general machinery,

mold,aviation,energy and traffic.

Machine Characteristics

1.The major machine components apply finest gray cast iron which are of good shock resistance.

All the casts have been done with aging treatment twice, in order to eliminate the internal residual

stresses. So that, our machine can work with high rigidity and good shock resistance for heavy cutting and intermittent cutting.

2.Key components are designed with CAD software, in this way, the optimal structure can be

analyzed out by computer, which ensure the good intensity,rigidity and thermal stability.

3.The joint face of components are manually polished well, which guarantees the effective contacting area.