Product Description

Increased Engine Output

Engine output has been increased,compared to the predecessor models, giving the system more torque for more powerful and faster movement. Furthermore,load peaks are compensated cleverly, meaning maximum torque is available at all times for maximum handling capacity.

High Swing Torque

The separate hydraulic pump in the closed slewing circuit only supplies hydraulic fluid to the swing mechanism. The maximum delivery volume is thus available at any time for turning the uppercarriage

for fast and dynamic rotational movements.

Sensitive Hydraulics

The optimal harmonisation between the engine and the control valve allows a fast and direct response from the hydraulics to the input command. This is controlled proportionally to enable smooth and gentle movements to be executed when the joystick is moved.

Cabin with Ergonomic Design

The modern cab design provides excellent conditions for healthy, concentrated and productive work in maximum comfort. The colour touchscreen display, the controls and operator's seat Comfort are all coordinated to form a perfect ergonomic unit. In addition the ergonomic joysticks allow the machine operation to be both pleasant and precise.

Dual power (Electric power + Diesel power)

Motor power:75kw

Diesel power: 118kw

Hydraulic transmission,

1.0 m³ clamshell bucket

A/C,

Optional: lifting magnet; five peel grab, sorting grab, log grapple etc.

Product Show

Specifications

Working Scope

Lifting Performance Parameters

Length of the boom is optional, and the optimum proportion can be obtained according to the actual demand of the work.

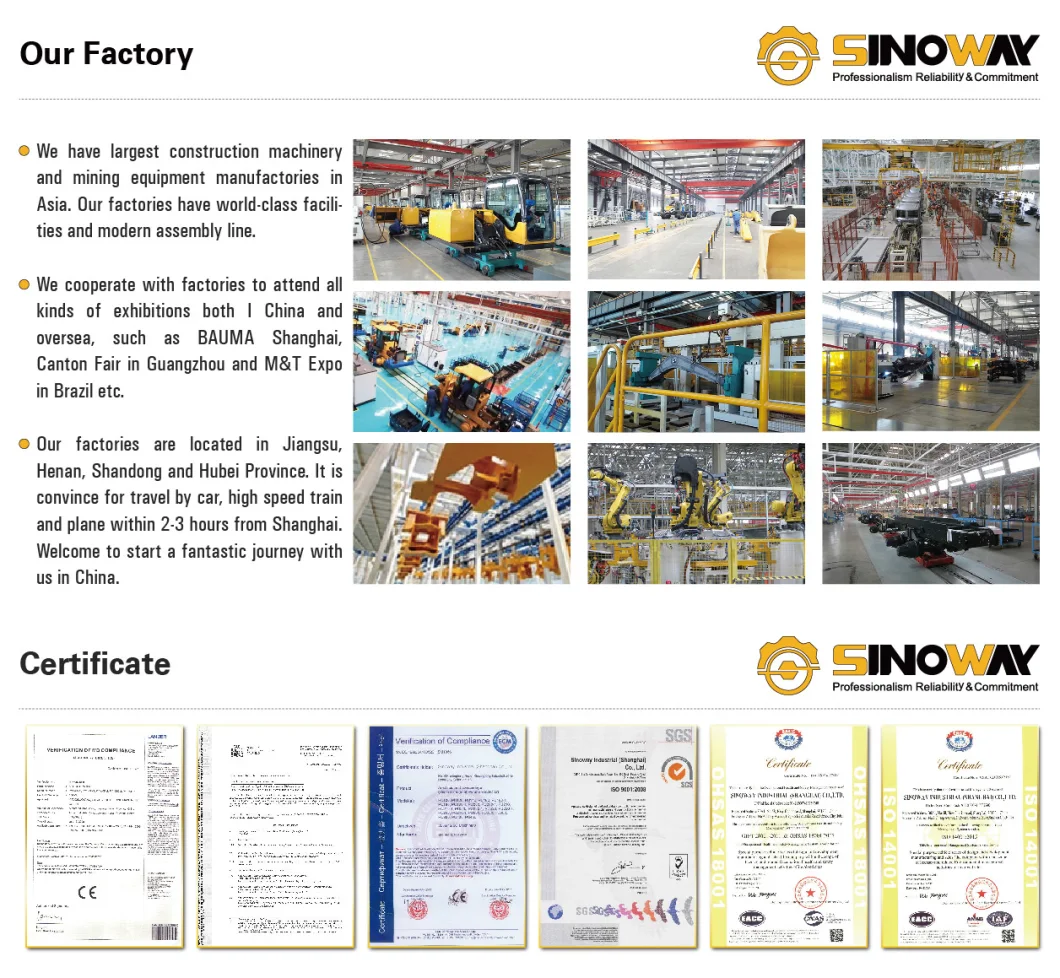

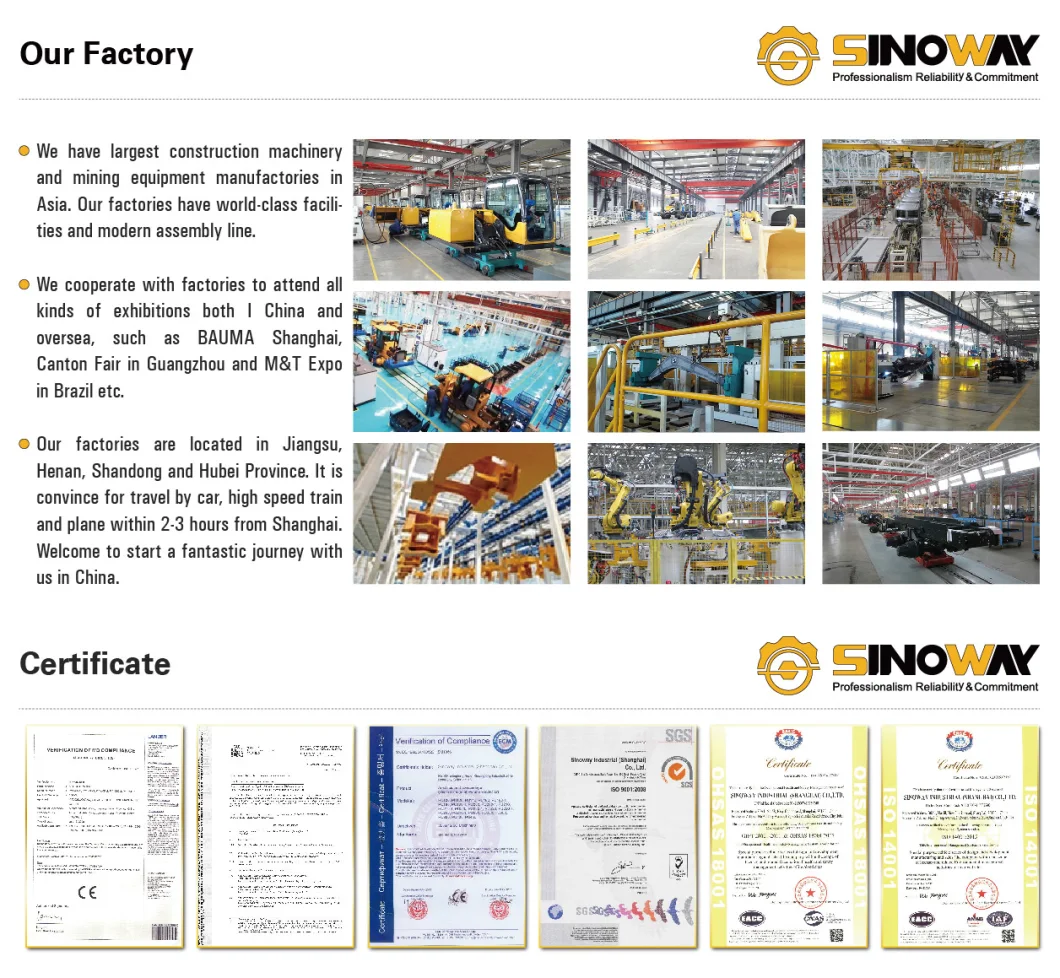

Why Choose Us

Increased Engine Output

Engine output has been increased,compared to the predecessor models, giving the system more torque for more powerful and faster movement. Furthermore,load peaks are compensated cleverly, meaning maximum torque is available at all times for maximum handling capacity.

High Swing Torque

The separate hydraulic pump in the closed slewing circuit only supplies hydraulic fluid to the swing mechanism. The maximum delivery volume is thus available at any time for turning the uppercarriage

for fast and dynamic rotational movements.

Sensitive Hydraulics

The optimal harmonisation between the engine and the control valve allows a fast and direct response from the hydraulics to the input command. This is controlled proportionally to enable smooth and gentle movements to be executed when the joystick is moved.

Cabin with Ergonomic Design

The modern cab design provides excellent conditions for healthy, concentrated and productive work in maximum comfort. The colour touchscreen display, the controls and operator's seat Comfort are all coordinated to form a perfect ergonomic unit. In addition the ergonomic joysticks allow the machine operation to be both pleasant and precise.

Dual power (Electric power + Diesel power)

Motor power:75kw

Diesel power: 118kw

Hydraulic transmission,

1.0 m³ clamshell bucket

A/C,

Optional: lifting magnet; five peel grab, sorting grab, log grapple etc.

Product Show

Specifications

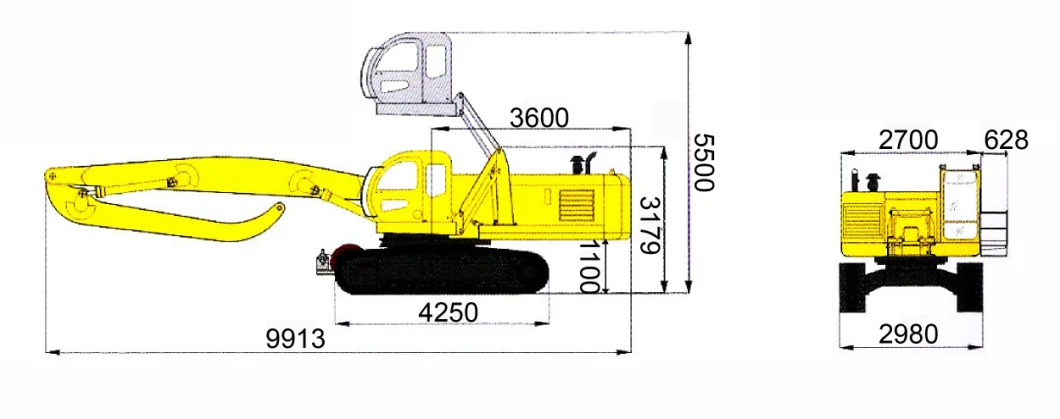

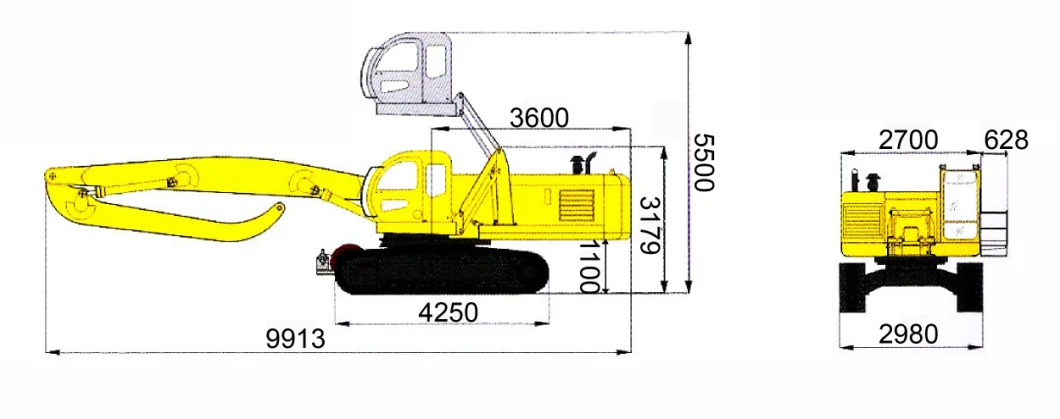

| Dimensions | |

| Machine length | 11000m |

| Machine height | 3190mm |

| Machine width | 3327mm |

| Track length | 4622mm |

| Maximum lift height of the cab | 4897mm |

| Tail turning radius | 3504mm |

| Turntable height off the ground | 1251mm |

| Turntable width | 2940mm |

| Width of walking platform | 627mm |

| Transportation dimensions exclude width of the walking platform. | |

| The cap is optional: | Fixed cab / heightened cab / lift-able cab |

Working Scope

Lifting Performance Parameters

| Radius | 3.5 | 4.5 | 6.0 | 7.5 | 9.0 | 10.5 |

| Height | ||||||

| Max. height | ||||||

| 12 | ||||||

| 10.5 | 7.0 | 5.0 | ||||

| 9 | 6.0 | 5.0 | ||||

| 7.5 | 5.9 | 4.9 | 4.0 | |||

| 6.0 | 7.0 | 5.8 | 4.7 | 3.9 | ||

| 4.5 | 10.0 | 6.8 | 5.7 | 4.6 | 3.8 | |

| 3.0 | 9.8 | 6.5 | 5.5 | 4.4 | 3.7 | 3.0 |

| 1.5 | 6.3 | 5.4 | 4.2 | 3.4 | 2.8 | |

| 0 | 6.0 | 5.2 | 4.1 | 3.2 | ||

| -1.5 | 5.0 | 4.0 | 3.0 | |||

| Max. depth |

Length of the boom is optional, and the optimum proportion can be obtained according to the actual demand of the work.

| Technical Parameters | |

| Power | |

| Engine | 154kw |

| Electric motor | 110kw |

| Fuel tank | 440L |

| Walking System | |

| Walking speed | 3.6/5.2km/h |

| Max. traction force | 160KN |

| Grade ability | 25% |

| Hydraulic System | |

| Max. flow | 2 x 214L/min |

| Max. working pressure | 31MPa |

| Hydraulic oil tank | 440L |

| Pilot pressure | 3.8MPa |

| Main Performance Parameters | |

| Total weight | 42t |

| Max. lifting moment | 50t.m |

| Max. swing speed | 8r/min (Single power type ) |

| Max. swing torque | 90KN.m |

Why Choose Us