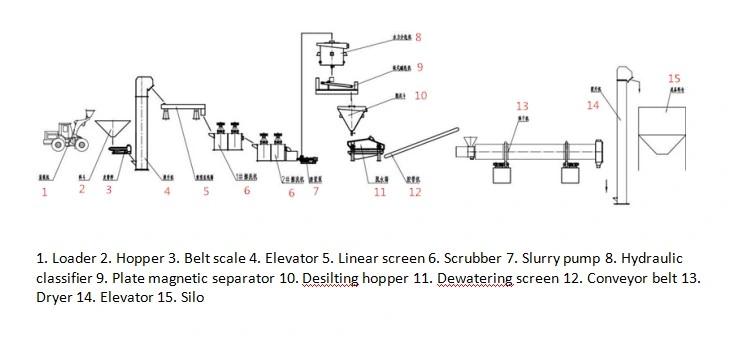

Frac Sand Processing Equipment Quartz Sand Petroleum Fracturing Sand plant

Preliminary consideration of the beneficiation process of this beneficiation production line is:

"raw ore----crushing----pre-screening-----scrubbing----desliming----coarse particle classification-----concentration----fine particle classification----plate magnetic separation----concentration----dewatering----drying----screening---- packaging----finished Product"

Equipment Introduction

1.GTYZ circular vibrating screen

1. Circular vibrating screen: the excitation force can be adjusted at any time, which is convenient for modular design and use

2. The sieving machine structure trend is simplified, and it is reasonable to improve the equipment manufacturing technology level and equipment accuracy.

3. Screening machine has high screening efficiency, large processing capacity and long service life.

4. Pre-selected particles, turf, tree roots and other impurities larger than 4 mesh to improve production efficiency and quality.

2.sand scrubbing machine

1. It is mainly used for the separation of slime and the removal of surface impurities. Pressurized scrubbing will purify the crushing rate, impurities, and non-rounded materials in advance, so as to reduce the crushing rate and purification.

2. Mild scrubbing, unique trough structure and impeller configuration, the scrubbing strength is improved by about 30% compared with the traditional scrubber with the same specifications.

3. Wear-resistant and corrosion-resistant, the tank is lined, and the impeller is made of wear-resistant materials, which has high corrosion resistance and wear resistance.

3.GSF hydraulic classifier

1. The material is subjected to the rising water flow in the cylinder, and the particle size is classified according to the specific gravity classification, which has high production efficiency and low energy consumption.

2. Equipped with an automatic control system, the adjustment of the operating parameters is simple, convenient and easy to control

3. The water tank below the cylinder is equipped with special devices. When the water is stopped, the ascending water hole is automatically closed, and the material in the cylinder will not block the water hole and enter the water tank

4. GTGB high gradient magnetic separator

It uses 4500GS-15000GS permanent magnet magnetic block. The material passes through the belt and the magnetic material is adsorbed. Then the belt rotates to separate the raw material from the magnetic material. It mainly reduces the crushing rate and acid solubility.

5.GTS Desliming equipment

Desliming the raw ore.

The preliminary separation of mud, sand, water, and so on reduces the water content in the material and reduces the pressure for the dewatering screen in the next step.

6. GTTS dewatering screen

It is used to wash and dehydrate the ore. Because the water content after the finished product is too high, it needs to be dewatered through a dewatering screen to reduce the water to a controllable range. The reduction of the water content can improve the efficiency of the dryer.

7.GHG sand dryer

The dehydrated quartz sand enters the drying furnace through a conveyor belt and is subjected to a high-temperature drying treatment to form a finished product.

We use tumbler direct heat dryer. According to the nature of the original ore and the requirements of the product, the drum can use two materials, one is stainless steel: the product has the advantages of wear resistance and no pollution, because the hardness of quartz is relatively high, and the use of stainless steel can effectively reduce the friction of quartz. High, another type of drum is made of carbon steel, which has the advantages of low cost and disadvantages: pollution, high iron content, and non-wear resistance. The whole dryer is equipped with environmental protection equipment such as dust removal gas.

The heat source of the dryer adopts natural gas combustion, diesel combustion or biological particle combustion, which fully complies with national environmental protection policies

8.GDS vibrating screen

Grading system: The materials produced by the dryer are classified, and qualified products can be classified in turn according to customer requirements. Our classification system adopts the mode of linear vibrating screen combination operation, which is the first in the quartz sand industry. The screen adopts a multi-piece combination design and adopts a nylon screen. The lower hopper of the drum sieve is lined with wear-resistant ceramic sheets, which not only improves the service life of the equipment, but also ensures the purity of the product.

Our company has optimized the traditional linear screen. It adopts wooden screen frame, stainless steel screen, and adds high white wear-resistant stretch ball. The use of high-quality high-elastic rubber springs not only increases the vibration force of the linear screen, but also reduces noise.

9. Environmental protection circulating water treatment

1.Waste water 2. Settling pond 3. Sediment 4. Regular cleaning 5.Sludge drying plant

6.Coagulation tank 7. Coagulant 8. Sedimentation tank 9. Filter press 10. Clear water pool

11. Recycling or meeting discharge standards 12. Outward transportation landfill

Flocculation sedimentation method in physical and chemical method: After the primary sedimentation of the washing wastewater, the large particulate matter in the wastewater is removed, and the effluent enters the coagulation reaction tank. The pollutants dissolved in the water body polymerize to form larger aggregate flocs (commonly known as "alum flowers"). Because the proportion of the "alum flowers" is greater than 1, it precipitates at the bottom of the water body under its own gravity, so Separation of pollutants from water bodies

Certificates

Company introduction

Customers

Contact

Ms.Yolanda