Introduction:

HHS high head slurry pumps are designed for handling highly abrasive, high density slurries with excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost, higher head per stage and higher pressure pumping system, commonly used for long distance transport lines. The HHS pumps can often satisfy working condition with a single pump in stead of multiple pumps in series. The lifting range is capable of handling medium size particles and pumping at heads in excess of 100 meters per stage.

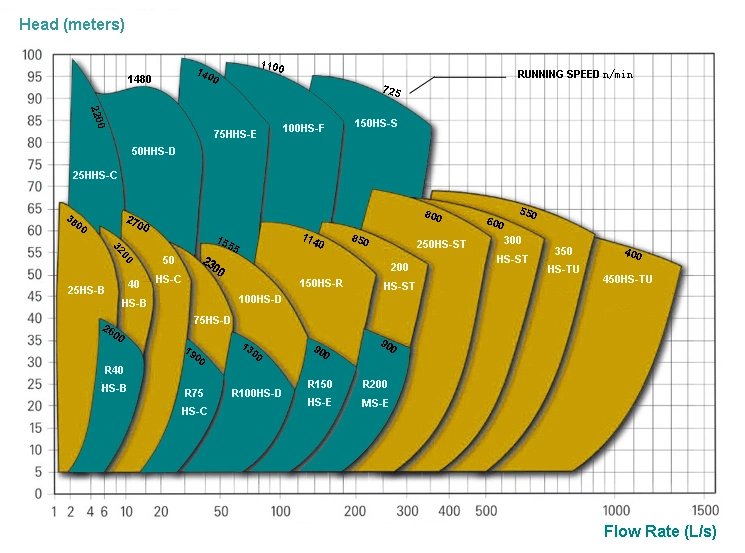

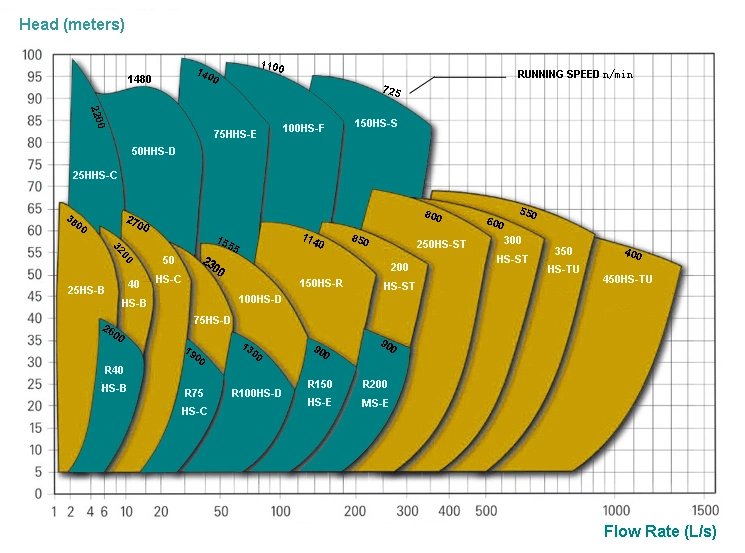

HHS series High Head Slurry Pumps Performance Parameters:

Application:

Features:

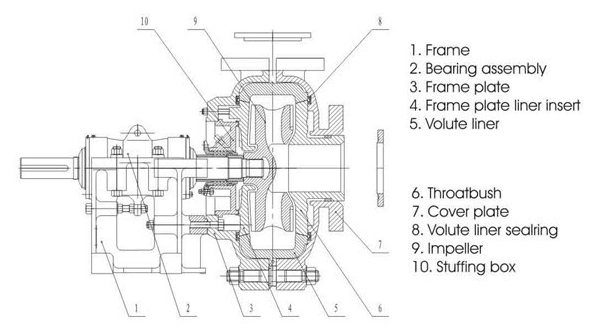

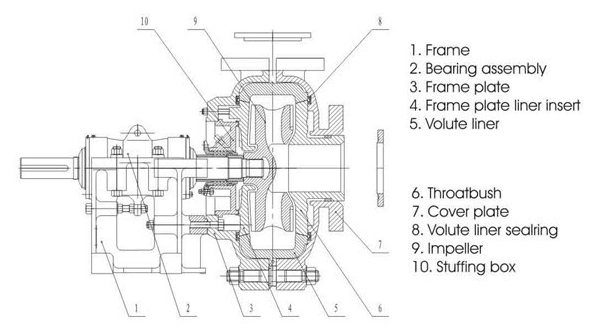

• High head, high pressure centrifugal end suction slurry pump design.

• Ductile iron fully lined casing provides durability, strength and long service life.

• Hyper wear resistance materials for longtime worklife.

• Multi-stage high pressure operation allowed.

• Heavy duty construction with through-bolt design provides ease of maintenance and results in less down time

• Large diameter, slow turning, high efficiency impellers result in maximum wear life and lower operating costs

• Large, open internal passages maximize wear life and lower operating costs

• Full flush gland, low flow, and dry running centrifugal seals reduce flush water usage minimizing pump operating costs.

Contact

Welcome to contact us any time for details.

Your inquiry will get our prompt attention and response !

HHS high head slurry pumps are designed for handling highly abrasive, high density slurries with excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost, higher head per stage and higher pressure pumping system, commonly used for long distance transport lines. The HHS pumps can often satisfy working condition with a single pump in stead of multiple pumps in series. The lifting range is capable of handling medium size particles and pumping at heads in excess of 100 meters per stage.

HHS series High Head Slurry Pumps Performance Parameters:

| Model | Max. Power (kw) | Clear Water Performance | Impeller | |||||

| Capacity Q (m3/h) | Head H (m) | Speed n (rpm) | Eff. η (%) | NPSH (m) | Vane No. | Impeller Dia. | ||

| 25HHS-C | 30 | 16.2-34.2 | 25-92 | 1400-2200 | 20 | 2--5.5 | 5 | 330 |

| 50HHS-D | 60 | 68.4-136.8 | 25-87 | 850-1400 | 47 | 3-7.5 | 5 | 457 |

| 75HHS-E | 120 | 126-252 | 12-97 | 600-1400 | 50 | 2-5 | 5 | 508 |

| 100HHS-F | 560 | 324-720 | 30-118 | 600-1000 | 64 | 3-8 | 5 | 711 |

| 150HHS-S | 560 | 468-1008 | 20-94 | 500-1000 | 65 | 4-12 | 5 | 711 |

| • Mining | • Mineral processing | • Coal prep | • Cyclone feeds |

| • Tunnel | • Chemical slurries | • Tailings | • Mill grinding |

| • Ash handing | • Paper and Pulp | • Waste sludge | • Coarse sand |

| • Lime mud | • Phosphoric acid | • Dredging | • Construction |

| • Alumina Industry | • Power Plant | • Potash Fertilizer Plant | • Other industries |

Features:

• High head, high pressure centrifugal end suction slurry pump design.

• Ductile iron fully lined casing provides durability, strength and long service life.

• Hyper wear resistance materials for longtime worklife.

• Multi-stage high pressure operation allowed.

• Heavy duty construction with through-bolt design provides ease of maintenance and results in less down time

• Large diameter, slow turning, high efficiency impellers result in maximum wear life and lower operating costs

• Large, open internal passages maximize wear life and lower operating costs

• Full flush gland, low flow, and dry running centrifugal seals reduce flush water usage minimizing pump operating costs.

Contact

Welcome to contact us any time for details.

Your inquiry will get our prompt attention and response !