20/18TU-AH High Chrome Alloy Cr27 Heavy Duty Slurry Pumps

Naipu® factory of slurry pump , gravel sand pump , dredging pump and Wear spare parts.

We are direct factory with 30 years's producing experience.

We own mould workshop,foundry workshop, machining workshop, assembly workshop and advanced test equipment. Naipu can be your factory in china.

In addition , We also can produce various spare parts according to the drawing

The Main pump model of AH HH M L SP AF G Series We are direct factory with 30 years's producing experience.

We own mould workshop,foundry workshop, machining workshop, assembly workshop and advanced test equipment. Naipu can be your factory in china.

In addition , We also can produce various spare parts according to the drawing

| AH series | L(R), M | HH | SP(R) | G | AF Series |

| 1.5/1B-AH(R) | 20A-L | 1.5/1 C-HH | 40PV-SP(R) | 6/4D-G | 2QV-AF |

| 2/1.5B-AH(R) | 50B-L(R) | 3/2D-HH | 65QV-SP(R) | 8/6E-G | 3QV-AF |

| 3/2C-AH(R) | 75C-L | 4/3E-HH | 100RV-SP(R) | 10/8F-G | 6SV-AF |

| 4/3C-AH(R) | 100 D-L | 4/3X-HH | 150SV-SP(R) | 10/8S-G | 8SV-AF |

| 6/4D-AH(R) | 150E-L | 6/4F-HH | 200SV-SP | 12/10G-G | |

| 6/4E-AH(R) | 300S-L | 6/4X-HH | 250TV-SP | 14/12G-G | |

| 8/6E-AH(R) | 10/8 R-M | 6S-H | 14/12T-G | ||

| 8/6R-AH(R) | 10/8 E-M | 8/6S-H | 16/14 G-G | ||

| 10/8F-AH(R) | 8/6X-H | 16/14TU-GH | |||

| 10/8X-AH(R) | 6S-HP | 16/14H-GH | |||

| 12/10ST-AH(R) | 8/6S-HP | 18/16G-G | |||

| 14/12ST-AH(R) | 8/6X-HP | 18/16 TU-GH | |||

| 16/14TU-AH(R) | |||||

| 20/18G(TU)-AH(R) |

20/18TU-AH High Chrome Alloy Cr27 Heavy Duty Slurry Pumps

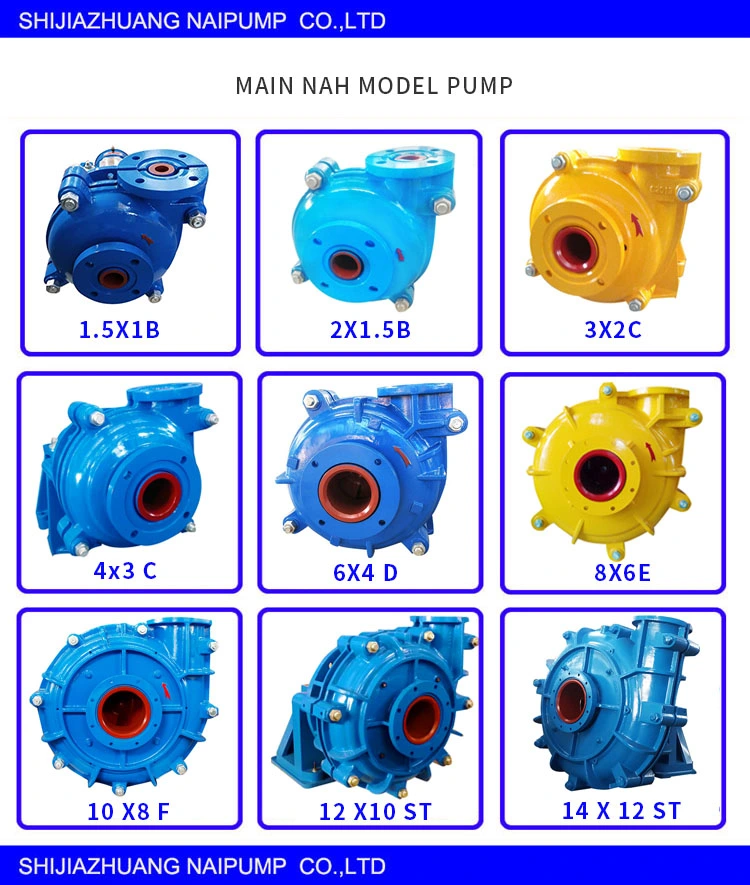

AH HH M Horizontal Slurry Pumps

Feature and Application:

Naipu® NP-AH(R) series centrifugal slurry pumps and spare parts can fully interchange with world famous brand.These pumps are of heavy-duty construction, designed for continuous pumping of highly abrasive and corrosive slurries. They feature a wide choice of replaceable abrasion resistant metal or moulded elastomer casting liners and Impellers, which are all interchangeable within a common casting assembly.

1.Double Liner Centrifugal Pump

2.Rubber or high chrome alloy impeller

3.Large flow in medium head

4.Drive type:ZV CV DC CR CL

5.Types of 4 seal to prevent leakage:Packing Seal # Expeller Seal # Mechanical Seal # Dyna Seal

Typical Applications---

Minerals Flotation Processing

Electric Factory Coal Preparation

Coal Washing

Chemical Medium Processing

Effluent Handling

Salt and Sugar Industry

Sand And Gravel Handling

HORIZONTAL SLURRY PUMP PERFORMANCE PARAMETERS

| Type | Allowable Mating Max. Power(Kw) | Clear Water Performance | Impeller | ||||||||

| Material | Capacity/Q m³/hr | Head/m | peed rpm | Max Eff% | NPSH/m | Nos of Vane | Impeller Diameter/ mm | ||||

| 1.5/1-NP-AH | 15 | M | 12.6--28.8 | 6--68 | 1200--3800 | 40 | 2--4 | 5 | 152 | ||

| R | 10.8-25.2 | 7-52 | 1400-3400 | 35 | 3 | ||||||

| 2X1.5-NP-AH | 15 | M | 32.4--72 | 6--58 | 1200--3200 | 45 | 3.5--8 | 5 | 184 | ||

| R | 25.2-54 | 5.5-41 | 1000-2600 | 50 | 2.5-5 | 178 | |||||

| 3X2-NP-AH | 30 | M | 39.6--86.4 | 12--64 | 1300--2700 | 55 | 4--6 | 5 | 214 | ||

| R | 36-75.6 | 13-39 | 1300-2100 | 55 | 2-4 | 213 | |||||

| 4X3-NP-AH | 30 | M | 86.4--198 | 9--52 | 1000--2200 | 71 | 4--6 | 5 | 245 | ||

| R | 79.2-180 | 5-34.5 | 800-1800 | 59 | 3-5 | ||||||

| 6X4-NP-AH | 60 | M | 162--360 | 12--56 | 800--1550 | 65 | 5--8 | 5 | 365 | ||

| R | 144-324 | 12-45 | 800-1350 | 65 | 3-5 | ||||||

| 8X6-NP-AH | 300 | M | 360--828 | 10--61 | 500--1140 | 72 | 2--9 | 5 | 510 | ||

| R | 324-720 | 7-49 | 400-1000 | 65 | 5-10 | ||||||

| 10X8-NP-AH | 560 | M | 612--1368 | 11--61 | 400--850 | 71 | 4--10 | 5 | 686 | ||

| R | 540-1188 | 12-50 | 400-750 | 75 | 4-12 | ||||||

| 12X10-NP-AH | 560 | M | 936--1980 | 7--68 | 300--800 | 82 | 6 | 5 | 762 | ||

| R | 720-1620 | 7-45 | 300-650 | 80 | 2.5-7.5 | ||||||

| 14X12-NP-AH | 560 | M | 1260--2772 | 13--63 | 300--600 | 77 | 3--10 | 5 | 965 | ||

| R | 1152-2520 | 13-44 | 300-500 | 79 | 3-8 | ||||||

| 16X14-NP-AH | 1200 | M | 1368--3060 | 11--63 | 250--550 | 79 | 4--10 | 5 | 1067 | ||

| 20X18-NP-AH | 1200 | M | 2520--5400 | 13--57 | 200--400 | 85 | 5--10 | 5 | |||

Horizontal Slurry Pump Constructure

NAH PUMP MATERIALS OPTION

| LINERS | IMPELLERS | CASING | BASE | EXPELLER | EXPELLER RING | SHAFT SLEEVE | SEALS | |

| Standard | Chrome Alloy Natural Rubber | Chrome Alloy Natural Rubber | SG Iron | SG Iron | Chrome Alloy or SG Iron | Chrome Alloy or SG Iron | SG Iron | Rubber and Nitrile |

| Options | Ferralium Hastelloy C 316 SS W151 Polyurethane Neoprene Butyl Viton Nitrile EPDM Hypalon | Ferralium Hastelloy C 316 SS W151 Polyurethane Neoprene Butyl Nitrile Hypalon | SG Iron Various grades | MS Fabricated Cast Iron | NI Resist Ferralium Hastelloy C Polyurethane 316 SS W151 | NI Resist Ferralium Hastelloy C 316 SS Rubber W151 Polyurethane Neoprene Butyl Nitrile | EN56C Ferralium Hastelloy C Titanium 316 SS 304 SS | Ceramic Stellite Chrome Oxide Nordel Neoprene Viton |

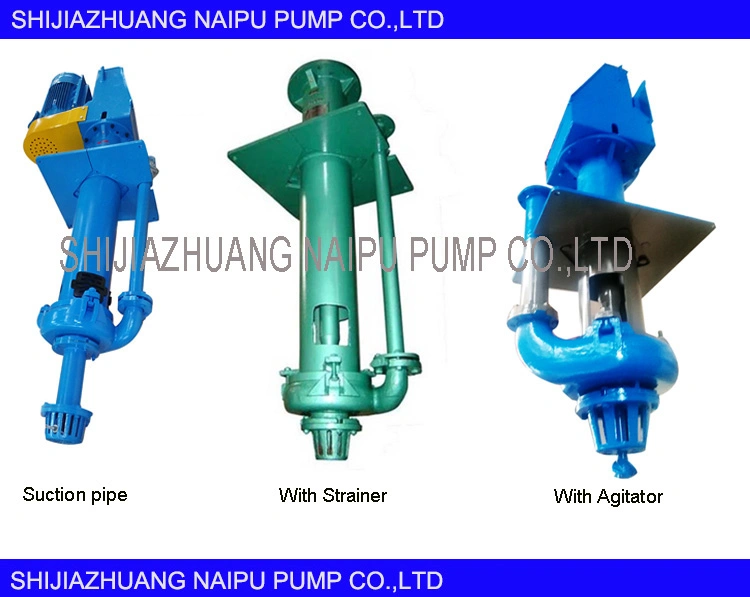

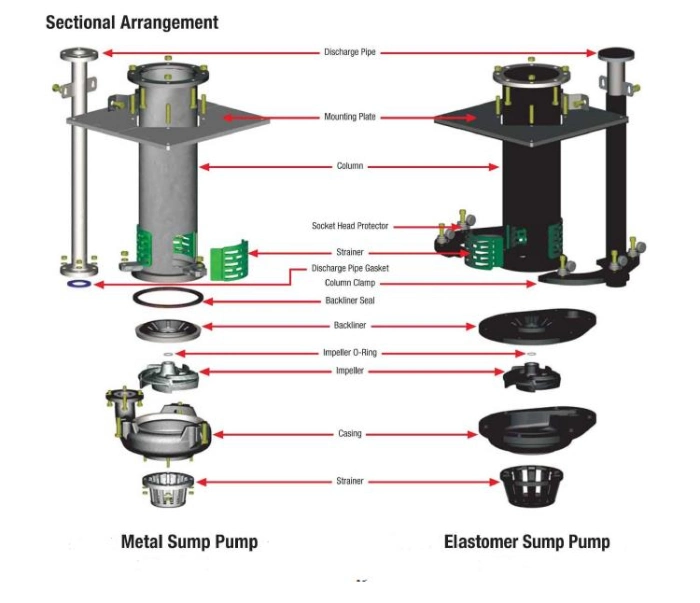

Vertical Slurry Pump

Feature and Application

Naipu® NP-SP pumps are vertical, centrifugal slurry pumps submerged in sump to work.They are designed for delivering abrasive,large particle and high density slurries.These pumps have no need of any shaft seal and sealing water. They can also be operated normally for insufficient suction duties.Wet parts of type NP-SP pump are made of abrasion-resistant metal. All parts of type NP-SP(R) pump immersed in liquid are lined with rubber outer liner.They are suited to transport non-edge angle abrasive slurry.

Typical Applications---

Sump drainage washdown

Floor drainage

Mill sumps

Carbon transfer

Monitoring

Magnetite mixing

NP-SP VERTICAL SLURRY PUMP PERFORMANCE PARAMETERS

| Type | Allowable Mating Max. Power(Kw) | Range Of Performance | Impeller | |||||

| Capacity/Q | Head/m | Speed/rpm | Max Efficiency/% | No. of Vanes | Impeller Diameter/mm | |||

| m³/hr | L/S | |||||||

| 40PV-NP-SP | 15 | 19.44-43.2 | 5.4-12 | 4.5-28.5 | 1000-2200 | 40 | 5 | 188 |

| 65QV-NP-SP | 30 | 23.4-111 | 6.5-30.8 | 5-29.5 | 700-1500 | 50 | 5 | 280 |

| 100RV-NP-SP | 75 | 54-289 | 15-80.3 | 5-35 | 500-1200 | 56 | 5 | 370 |

| 150SV-NP-SP | 110 | 108-479.16 | 30-133.1 | 8.5-40 | 500-1000 | 52 | 5 | 450 |

| 200SV-NP-SP | 110 | 189-891 | 152.5-247.5 | 6.5-37 | 400-850 | 64 | 5 | 520 |

| 250TV-NP-SP | 200 | 261-1089 | 72.5-302.5 | 7.5-33.5 | 400-750 | 60 | 5 | 575 |

| 300TV-NP-SP | 200 | 288-1267 | 80-352 | 6.5-33 | 350-700 | 50 | 5 | 61 |

Vertical Slurry Pump Constructure

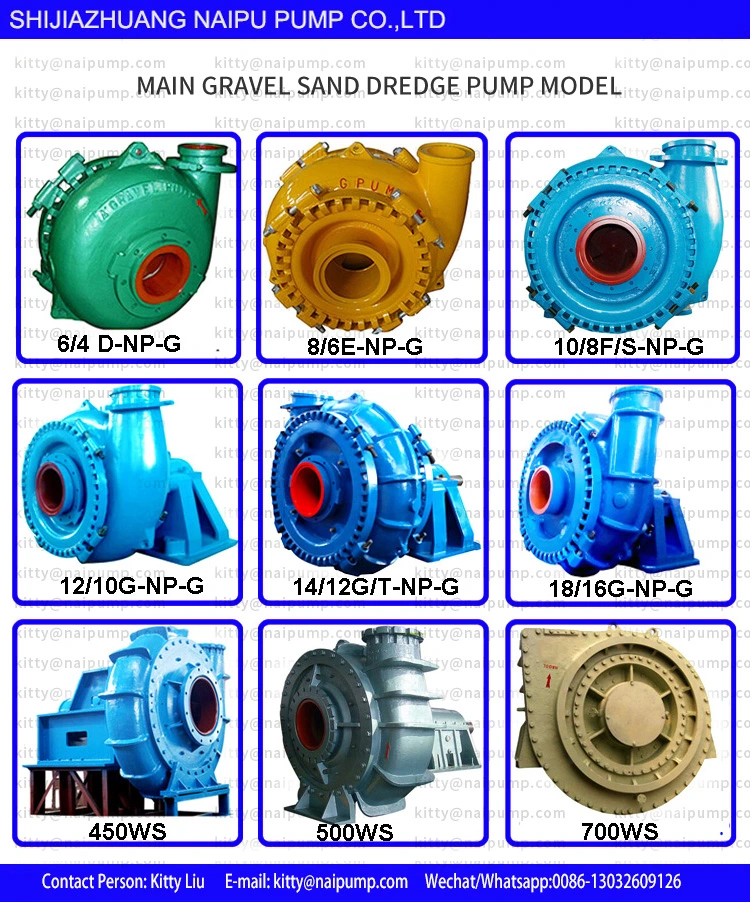

Horizontal Gravel Sand Pump

Feature and Application

Naipu® NP-G series of Dredge and Gravel pumps is designed specifically for continuous pumping of extremely aggressive slurries, with a wide particle size distribution. Capable of handling large particles at consistently high efficiencies results in low cost of ownership. The large volume internal profile of the casing reduces associated velocities further increasing component life.

Typical Applications---

Slag Granulation

Suction Hopper Dredging

Dredging

Barge Loading

Sand Reclamation

Sugar Beet

GRAVEL SAND PUMP PERFORMANCE PARAMETERS

| Pump Model | Allowable Max. Power (kW) | Clear Water Performance | ||||||

| Capacity Q | Head H(m) | Speed n(r/min) | Max.Eff. η% | NPSH (m) | Impeller Dia. | |||

| m3/h | l/s | |||||||

| 6/4D-G | 60 | 36-250 | 10-70 | 5-52 | 600-1400 | 58 | 2.5-3.5 | 378 |

| 8/6E-G | 120 | 126-576 | 35-160 | 6-45 | 800-1400 | 60 | 3-4.5 | 378 |

| 10/8S-GH | 560 | 216-936 | 60-260 | 8-52 | 500-1000 | 65 | 3-7.5 | 533 |

| 10/8S-G | 560 | 180-1440 | 50-400 | 24-30 | 500-950 | 72 | 2.5-5 | 711 |

| 12/10G-G | 600 | 360-1440 | 100-400 | 10-60 | 400-850 | 65 | 1.5-4.5 | 667 |

| 12/10G-GH | 1200 | 288-2808 | 80-780 | 16-80 | 350-700 | 73 | 2.0-10.0 | 950 |

| 14/12G-G | 1200 | 576-3024 | 160-840 | 8-70 | 300-700 | 68 | 2.0-8.0 | 864 |

| 16/14TU-GH | 1200 | 324-3600 | 90-1000 | 26-70 | 300-500 | 72 | 3.0-6.0 | 1270 |

| 18/16T-G | 1200 | 720-4320 | 200-1200 | 12-48 | 250-500 | 72 | 3.0-6.0 | 1067 |

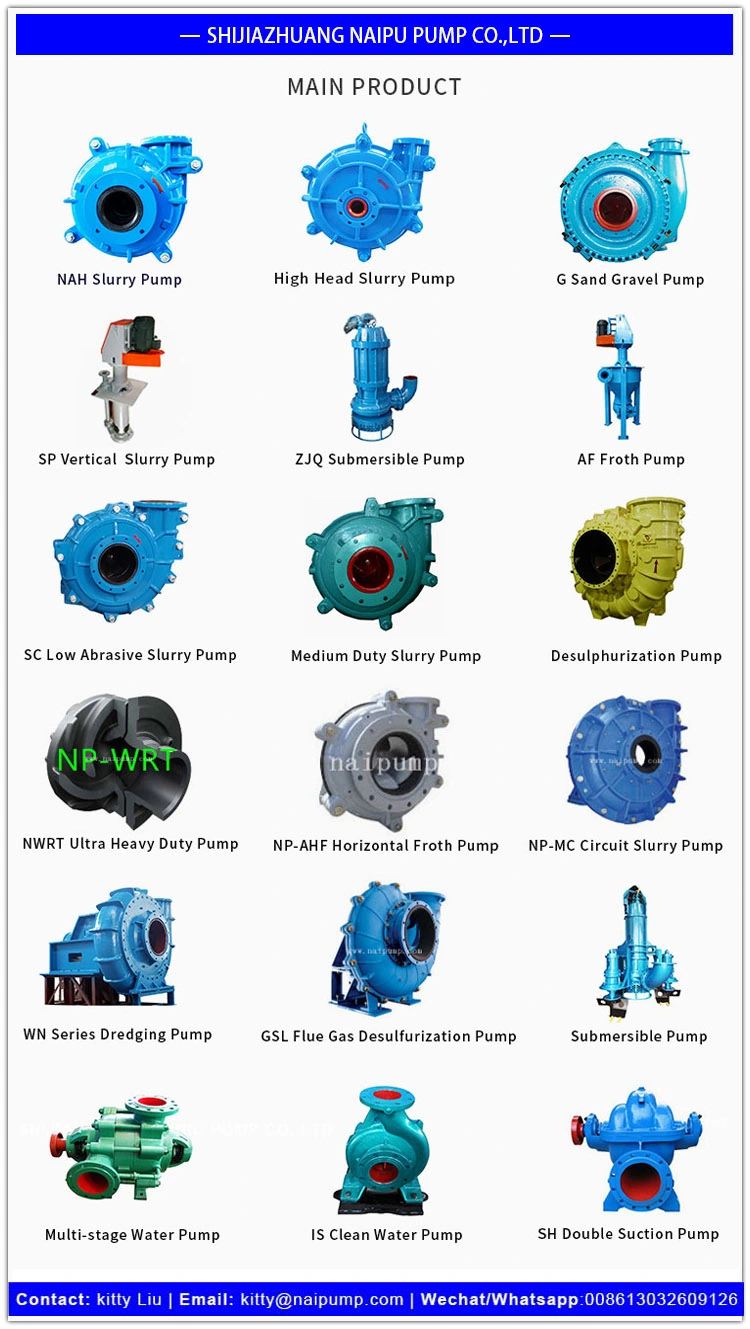

Naipu Main Pump Model

1. NAH , HH L Horizontal Slurry Pump

2. SP Vertical sump pump

3. ZJQ Submersible slurry pump

4. G Horizontal sand gravel pump

5. ZJQ Submersible sand pump

6. WS Dredging pump

7. AF Vertical Froth Pump

8 .AHF Horizontal Froth Pump

9. TL(R) Desulphurization Pump

10.Clean Water Pump

11. OEM Casting machinery wear parts

Spare Parts

Impeller, Volute Liner, Casing, ThroatBush, Frame Plate Liner Insert, Cover Plate, Frame Plate, Pump Liner Expeller, Expeller Ring, Stuffing Box, Expeller, Pump Shaft, shaft sleeve, Shaft Spacer, Bearing Assembly, Base, Stuffing Box, Gland Assembly, Bearing Housing, Lantern Ring, pump discharge pipe, flange, and so on.

OEM Service

Based on many years of rich experience in slurry pump manufacturing and design, NAIPU can undertake OEM customization for the whole set of pump and various spare parts. The slurry pump spare parts can be made of various material according to customer's requirement, Such as: Alloy 20, Hastelloy Alloy, A 61 and so on.

Our company undertakes the design, processing and transformation of various special pump parts. According to the user's requirements, Naipu Factory can manufacture various materials and components to meet the needs of different working conditions. Or in accordance with user requirements on the existing equipment technology transformation, combined with our company's rich hydraulic model, through advanced computer simulation technology, to provide users with a complete and effective solution.

Application:

The parts are widely used in Main Applications: Heavy Mining Mineral Processing Sand and Gravel Coal Prep Cyclone Feeds Aggregate Processing Fine Primary Mill Grinding Chemical Slurry Service Tailings Secondary Grinding Industrial Processing Pulp And Paper Food Processing Cracking Operations Ash Handling Pipeline Transport High Velocity Hydraulic Transport Food Processing Explosive Sludge In Metal Smelting River And Pond Dredging Heavy Refuse Removal Larger Particle Or Low NPSHA Applications Continuous (Snore) Sump Pump Operation Abrasive Slurries High Density Slurries Large Particle Slurries Sump Drainage Wash down Floor Drainage Mixing Iron Ore Cooper Diamond Alumina Coal Gold Kaolin Phosphorite Steel Palm Suger Chemical Power FGD Frac Sand Blending Construction City Sewage etc.

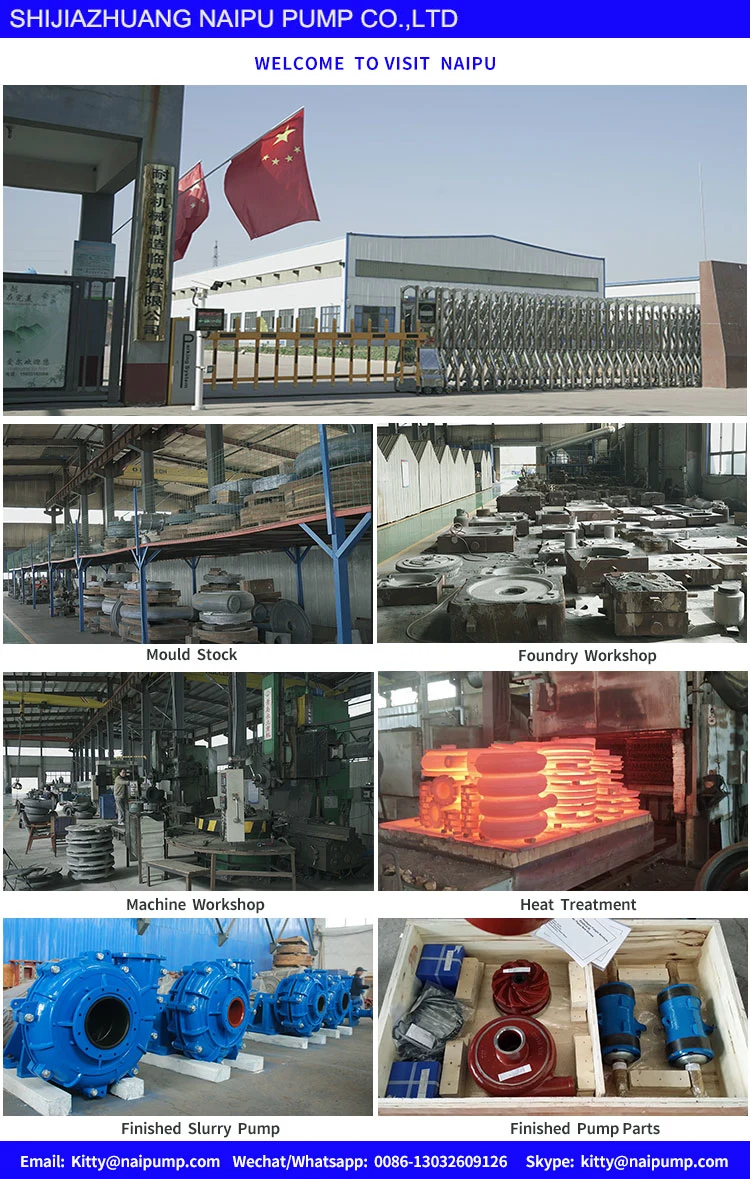

WorkShop

Shijiazhuang NaiPu Pump Co., Ltd have own Foundry workshop, Machining Workshop, Assembly workshop, and advanced test equipment.

Welcome to visit our factory!

FAQ

1. What Products does naipu pump mainly produce?

Naipu mainly Produce Slurry Pump, Gravel sand Pump, Dredging Pump, Centrifugal water pump and Spare Parts. Not only Pump parts, but also others wear casting parts if there is drawing or sample.

2. Is Naipu direct factory or trader?

Naipu own foundry workshop, Machining Workshop, and Assembly workshop.

The factory is located in ShiJiazhuang City, Hebei , China,covers an area of 30,000m.

Welcome to visit Naipu factory anytime.

3. The Min MQQ

The MQQ is one PCS spare parts.

4. What information is required for quotes?

If you need the spare parts, we need to know the parts Code and material.

If you need the whole pump set, we need to know the usage? The flow, head, and SG, Corrosive or not? The more detailed the better.

Welcome to Contact Me

ShiJiaZhuang NaiPu Pump Co., Ltd

Contact person: Kitty Liu

Shijiazhuang, Headquarters

Add.: No. 368, Xinshi North Road, Shijiazhuang, Hebei Province, China