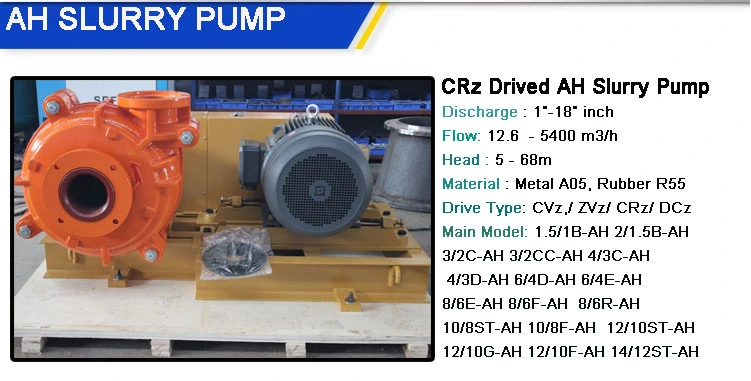

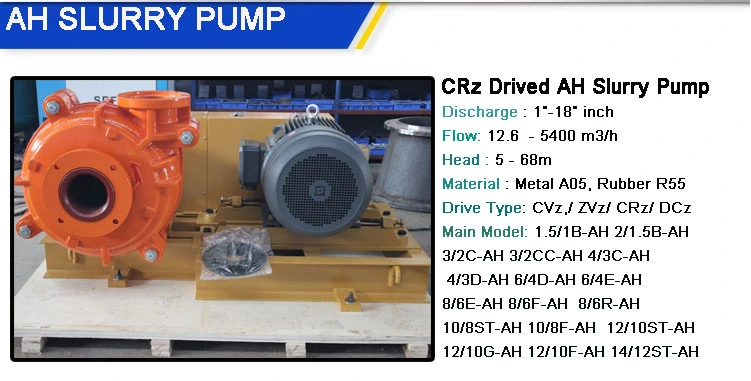

1-18 Inch Centrifugal Slurry Pump for Coal Washing Plant

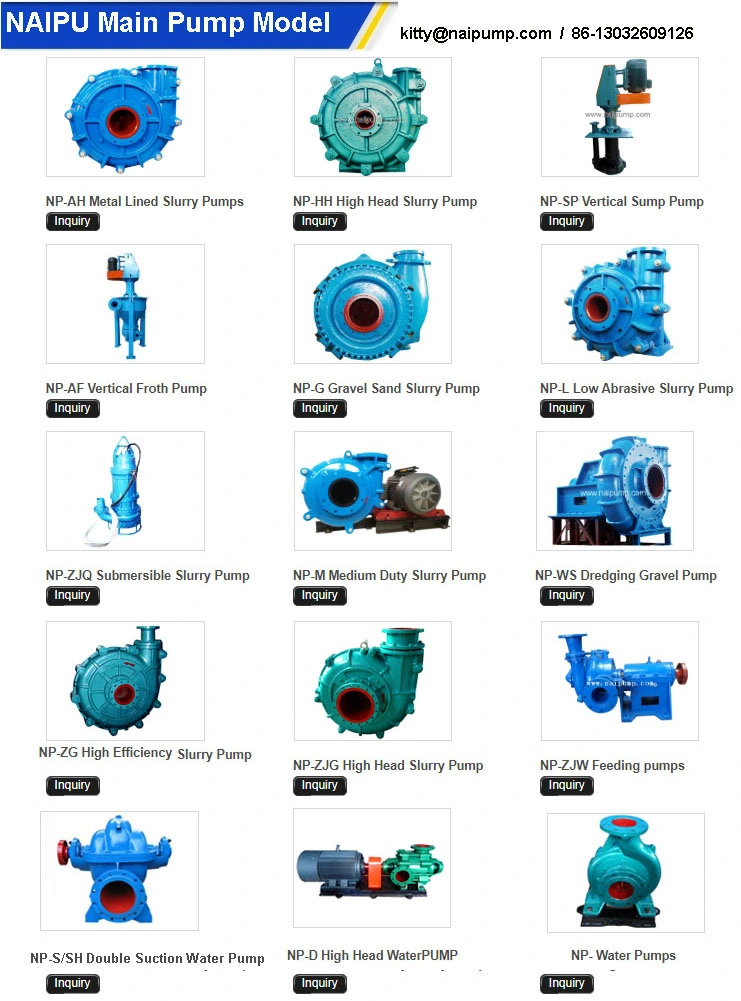

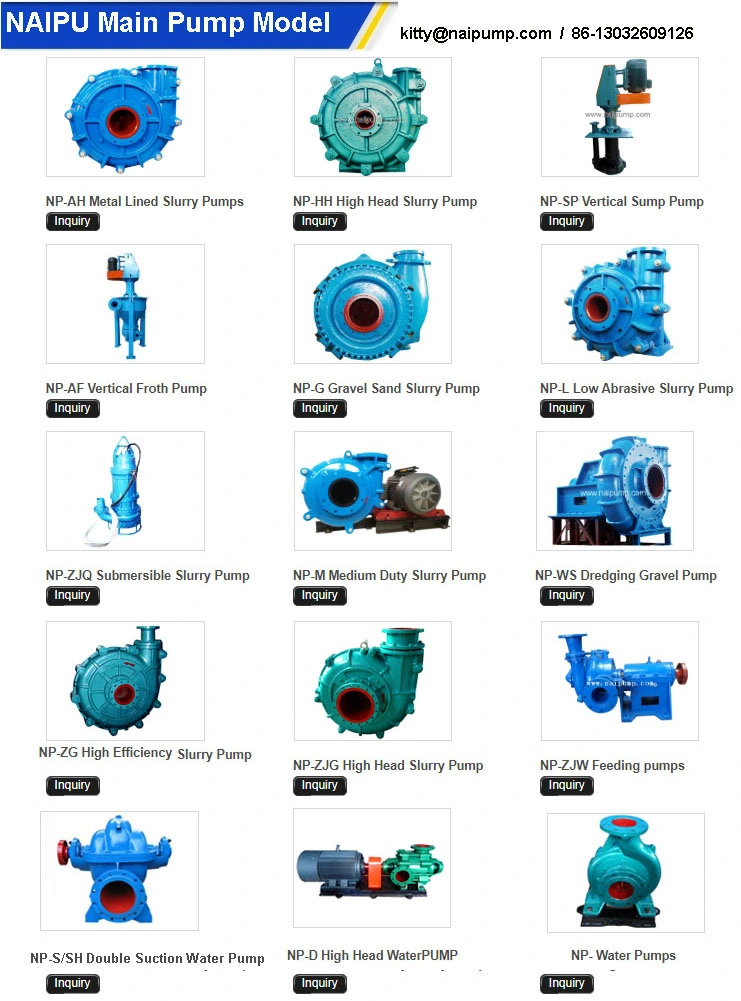

Naipu® factory of slurry pump , gravel sand pump , dredging pump and spare parts. Naipu can be your china factory. Welcome to contact me for catalogue.

1-18 Inch Centrifugal Slurry Pump

Welcome to contact us

Naipu® factory of slurry pump , gravel sand pump , dredging pump and spare parts. Naipu can be your china factory. Welcome to contact me for catalogue.

1-18 Inch Centrifugal Slurry Pump

Model Explanation

1.5x1B-NP

1.5: Intake diameter (inch)

1: Discharge size (inch)

B: Frame type with maximum power

HC: Shijiazhuang NaiPu Pump Co., Ltd.

ZJ(R) / ZJM/ZJH Slurry Pump Performance Parameters

Feature

Type ZJR, ZJM, ZJH Pump are cantilevered, horizontal, centrifugal slurry pump. They are designed for the handing high density slurries in the metallurgical, mining , coal, power, building material and other industrial department etc.

The frame plates liner and impeller for type ZJR , ZJ(M) pumps have replaceable wear-resistant metal liners or rubber liners.

The shaft seals for type ZJ(R),ZJM, and ZJH Pump may be adoptable of gland seal , expeller seal or Mechanical seal .

The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications.

Bearing assembly use cylindrical structure, which helps adjust the space between impeller and cover plate liner easily, and being removed completely when being repaired. Bearings use grease lubrication. Here are the drive types, such as V belt drive, gear reducer drive, fluid coupling drive, and frequency conversion drive devices.

Wide performance, good NPSH and high efficiency, the pump of this type may be installed in multistage series to meet the delivery for long distance.

Application

ZJR, ZJM, ZJH pumps are using for handing strong abrasive, high density slurries and low density, high head slurries in the metallurgical, mining, coal, power, building material and other industrial departments etc.

For example: Coal washery processing, handling with the fine ore and tailings in metal mine, handing combined bottom and fly ash in a thermal power station.

Typical Application

Spare parts for slurry pump

Workshop1.5x1B-NP

1.5: Intake diameter (inch)

1: Discharge size (inch)

B: Frame type with maximum power

HC: Shijiazhuang NaiPu Pump Co., Ltd.

ZJ(R) / ZJM/ZJH Slurry Pump Performance Parameters

| Type | Allowable Mating Max. Power(Kw) | Clear Water Performance | Impeller | ||||||

| Material | Capacity/Q m³/hr | Head/m | peed rpm | Max Eff% | NPSH/m | Nos of Vane | Impeller Diameter/ mm | ||

| 1.5/1-NP-AH | 15 | M | 12.6--28.8 | 6--68 | 1200--3800 | 40 | 2--4 | 5 | 152 |

| R | 10.8-25.2 | 7-52 | 1400-3400 | 35 | 3 | ||||

| 2X1.5-NP-AH | 15 | M | 32.4--72 | 6--58 | 1200--3200 | 45 | 3.5--8 | 5 | 184 |

| R | 25.2-54 | 5.5-41 | 1000-2600 | 50 | 2.5-5 | 178 | |||

| 3X2-NP-AH | 30 | M | 39.6--86.4 | 12--64 | 1300--2700 | 55 | 4--6 | 5 | 214 |

| R | 36-75.6 | 13-39 | 1300-2100 | 55 | 2-4 | 213 | |||

| 4X3-NP-AH | 30 | M | 86.4--198 | 9--52 | 1000--2200 | 71 | 4--6 | 5 | 245 |

| R | 79.2-180 | 5-34.5 | 800-1800 | 59 | 3-5 | ||||

| 6X4-NP-AH | 60 | M | 162--360 | 12--56 | 800--1550 | 65 | 5--8 | 5 | 365 |

| R | 144-324 | 12-45 | 800-1350 | 65 | 3-5 | ||||

| 8X6-NP-AH | 300 | M | 360--828 | 10--61 | 500--1140 | 72 | 2--9 | 5 | 510 |

| R | 324-720 | 7-49 | 400-1000 | 65 | 5-10 | ||||

| 10X8-NP-AH | 560 | M | 612--1368 | 11--61 | 400--850 | 71 | 4--10 | 5 | 686 |

| R | 540-1188 | 12-50 | 400-750 | 75 | 4-12 | ||||

| 12X10-NP-AH | 560 | M | 936--1980 | 7--68 | 300--800 | 82 | 6 | 5 | 762 |

| R | 720-1620 | 7-45 | 300-650 | 80 | 2.5-7.5 | ||||

| 14X12-NP-AH | 560 | M | 1260--2772 | 13--63 | 300--600 | 77 | 3--10 | 5 | 965 |

| R | 1152-2520 | 13-44 | 300-500 | 79 | 3-8 | ||||

| 16X14-NP-AH | 1200 | M | 1368--3060 | 11--63 | 250--550 | 79 | 4--10 | 5 | 1067 |

| 20X18-NP-AH | 1200 | M | 2520--5400 | 13--57 | 200--400 | 85 | 5--10 | 5 | 1370 |

Feature

Type ZJR, ZJM, ZJH Pump are cantilevered, horizontal, centrifugal slurry pump. They are designed for the handing high density slurries in the metallurgical, mining , coal, power, building material and other industrial department etc.

The frame plates liner and impeller for type ZJR , ZJ(M) pumps have replaceable wear-resistant metal liners or rubber liners.

The shaft seals for type ZJ(R),ZJM, and ZJH Pump may be adoptable of gland seal , expeller seal or Mechanical seal .

The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications.

Bearing assembly use cylindrical structure, which helps adjust the space between impeller and cover plate liner easily, and being removed completely when being repaired. Bearings use grease lubrication. Here are the drive types, such as V belt drive, gear reducer drive, fluid coupling drive, and frequency conversion drive devices.

Wide performance, good NPSH and high efficiency, the pump of this type may be installed in multistage series to meet the delivery for long distance.

Application

ZJR, ZJM, ZJH pumps are using for handing strong abrasive, high density slurries and low density, high head slurries in the metallurgical, mining, coal, power, building material and other industrial departments etc.

For example: Coal washery processing, handling with the fine ore and tailings in metal mine, handing combined bottom and fly ash in a thermal power station.

Typical Application

| Ball mill discharge | Bottom/fly ash, lime grinding | Coal | Coarse sand |

| Coarse tailings | Dredging | FGD | Fine tailings |

| Flotation | Heavy media | Minerals concentrate | Mineral sands |

| Ni acid slurry | Oil sands | Phosphoric acid | Phosphate matrix |

| Process chemical | Pulp and paper | Rod mill discharge | SAG mill discharge |

| Wet crushers | Alumina | Copper | Molybdenum |

| Iron Ore | Gold | Lead &zinc | Silver |

| Bauxite | Titanium | Steel | Sand & Gravel |

Spare parts for slurry pump

| Slurry Pump Basic Part No. | Material Code | Part Name |

| 147 | A05,A07,A49, R26,R08,R55,R33…. | Impeller |

| 001 | E62 | Adjusting Screw |

| 003 | G01 | Base |

| 004 | G01 | Bearing Housing |

| 005 | Bearing Assembly | |

| 009 | Bearing | |

| 011 | E62 | Clamp Washer |

| 013 | D20 | Cover Plate |

| 015 | E62 | Cover Plate Bolt |

| 017 | R26A R08, R55, R33 ,S21, S42,S31… | Cover Plate Liner |

| 018 | R26A R08, R55, R33 ,S21, S42,S31… | Cover Plate Liner |

| 024 | E62 | End Cover |

| 028 | G01,A05, C23 | Expeller |

| 029 | G01,A05, C23 | Expeller Ring |

| 029R | R08, R26,R55,R33 | Expeller Ring (Rubber) |

| 032 | D20 | Frame Plate |

| 034 | E62 | Frame Plate Bolt |

| 036 | R26A R08, R55, R33 ,S21, S42,S31… | Frame Plate Liner |

| 039 | E63 | Frame Plate Stud |

| 041 | A05,A07, A49, R26,R08,R55,R33….. | Frame Plate Liner Insert |

| 044 | G01, K24,C23 | Gland Assembly |

| 060 | Rubber | Intake Joint |

| 062 | G01 | Labyrinth |

| 063 | 1Cr18Ni9Ti | Lantern Ring |

| 064 | Rubber | Impeller O Ring |

| 067 | E62 | Neck Ring |

| 070 | E05 | Shaft Key |

| 073 | E05 | Shaft |

| 075 | D20 | Shaft Sleeve |

| 076 | D20 | Shaft Sleeve(Long) |

| 078 | G01, A05 | Stuffing Box |

| 081 | E02 | Keeper Plate |

| 083 | A05,R26A | Throat Bush |

| 085 | E02 | Cotter |

| 090 | S10 | Lip Seal |

| 109 | Rubber | Shaft O Ring |

| 110 | A05,A07,A49 | Volute Liner |

| 111 | Q05 | Packing |

| 117 | E62 | Shaft Spacer |

| 118 | 1Cr18Ni9Ti | Lantern Restrictor |

| 122 | Rubber | Expeller Ring/ Stuffing Box Seal |

| 124 | Rubber | Volute liner Seal |

| 125 | Rubber | Volute Frame Seal |

| 132 | Rubber | Discharge Joint Ring |

| 138 | E62 | Grease Cup Adaptor |

| 217 | Rubber | Impeller O Ring |

| 239 | C23 | Impeller Release Collar |

Our Service

1. Quick Reply

Your inquiry related to our products or prices will be

replied within 12 hours.

2.Pump Choice .

We can help to select the suitable pump

3.Technical Surport .

We have a group of high quality technicians with rich experience who can solve everything during the whole process.

4.Guarantee quality.

All the products have proved by ISO 9001:2008, CE, SGS. And also will be inspected strictly before delivery.

5.Perfect after -sales .

We will be responsible for the whole life period

6.OEM order.Many material are available ,like High chrome, rubber , stainless steel and etc.Steely alloy.

1. Quick Reply

Your inquiry related to our products or prices will be

replied within 12 hours.

2.Pump Choice .

We can help to select the suitable pump

3.Technical Surport .

We have a group of high quality technicians with rich experience who can solve everything during the whole process.

4.Guarantee quality.

All the products have proved by ISO 9001:2008, CE, SGS. And also will be inspected strictly before delivery.

5.Perfect after -sales .

We will be responsible for the whole life period

6.OEM order.Many material are available ,like High chrome, rubber , stainless steel and etc.Steely alloy.

Welcome to contact us

Shijiazhuang Naipu Pump Co., Ltd

Website: naipump.en.made-in-china.com